Cavity Trays provides gas control solutions for contaminated sites.

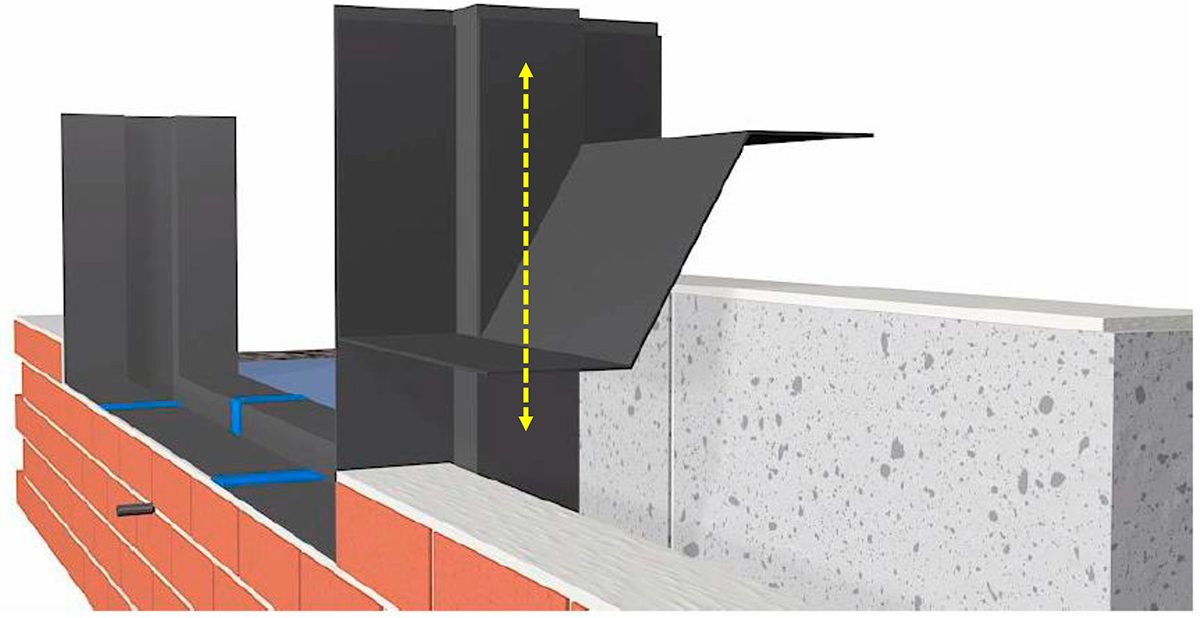

Getting DPC details correctly executed on site can be challenging, particularly when there is the additional consideration of constructing on gas-emitting (contaminated) land. The usual requirement for DPCs is to prevent rising damp, which is fairly straightforward. But when one adds the need to control penetrating damp, and at the same time prevent rising gas from continuing its upward journey beyond ground level, it becomes more involved.

Inadequate and poorly executed DPC placements

Often, the most difficult areas are door openings, which require sealing in and around to prevent gas infiltration into the structure, while also simultaneously shaping everything so penetrating water can get out. And what about the water from the cavity closers? Those Building Regulation fins ensure it discharges below sill level, but how does it get out without the gas getting in?

An alternative approach is to consider the use of preformed cavitrays and gas-control solutions. Ready-shaped barrier lengths integrate with preformed angles and stepped units. Wherever a ground-level door opening is encountered, a threshold tray protects under the sill and rises to a determined height either side. To these rising sides fit adjustable links, enabling unpunctuated protection continuity against water and gas. Water gravitating via the closer fins is received into the integral channel of the tray under the sill, and safely discharged via a flexible conduit running to the exterior. This is one of more than 200 solutions from Cavity Trays, the longest-established tray specialist and the only UK tray designer/manufacturer awarded European Technical Approval.

Cavity Trays Ltd.

enquiries@cavitytrays.co.uk

www.cavitytrays.co.uk