Watch our webinar in collaboration with Medite Smartply, which explores the importance of building with wood.

In association with![]()

Most of us know in a general way that timber is a good, environmentally sound material to use. But if architects are to achieve their environmental objectives, and to persuade clients of them, then a closer understanding of the benefits is necessary. This webinar, in collaboration with MEDITE SMARTPLY, aimed to help in that process, moving from the general and very pressing arguments to specific manufacturing information and the example of one specific project.

Speakers from left to right: Peter Smith, Daniel Doran, Roly Ward, and Matt Kennedy

Doctor Matt Kennedy, associate director for carbon and climate at Arup, is well-placed to give an overall view, having been involved in EU negotiations on COP21 in Paris. He explained the reasons behind the drive for net zero and construction’s importance, as it is responsible for approximately 50 per cent of all virgin materials extracted.

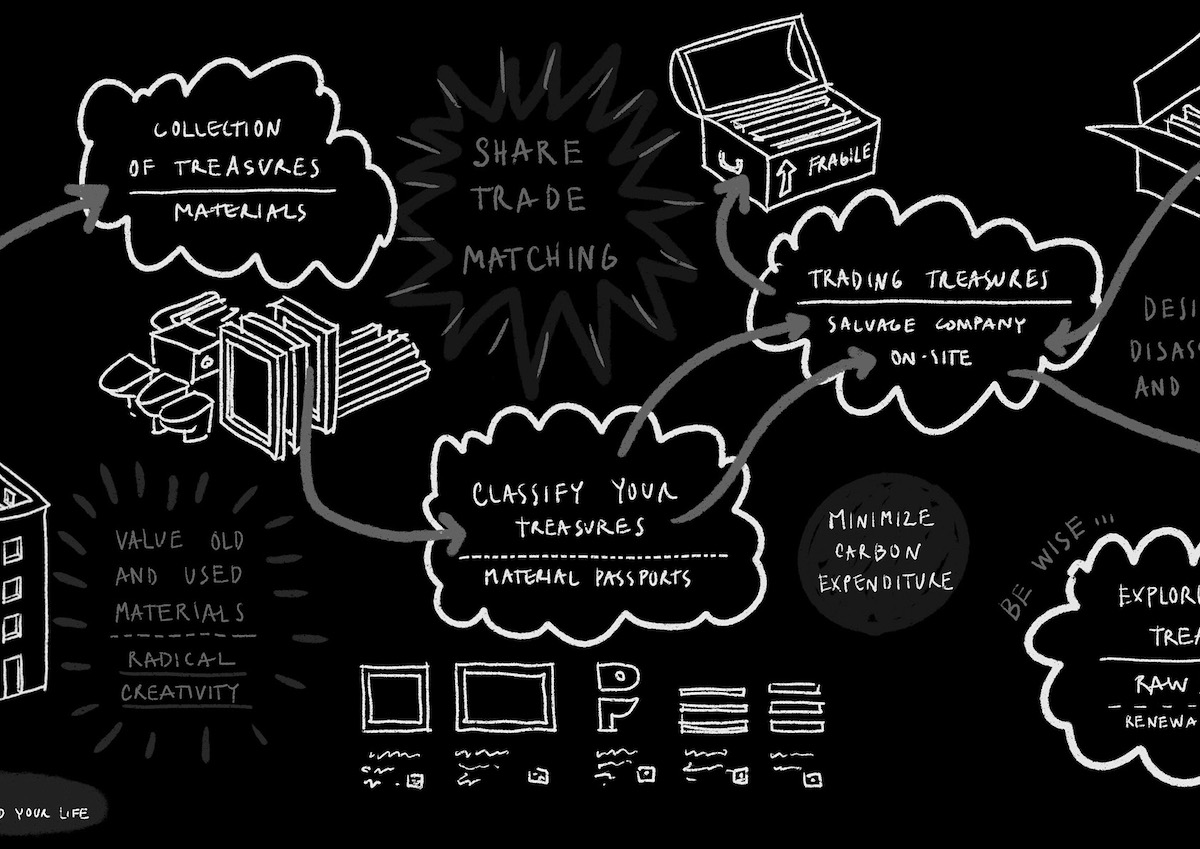

Moving towards net zero will also benefit organisations, he said, as it will improve their performance and give them a ‘first mover’ advantage. In order to achieve our aims, he said, ‘we want to maximise the life of products and materials while we regenerate more natural materials. You want to keep products in use and to sequester carbon within the soil and within your products.’

It is essential, he explained, to make buildings that are resilient and durable. Consultants, he said, should refuse any unnecessary new construction and rethink buildings. Putting separate functions into different buildings can help, as can ensuring that a building can be used throughout the day and not just for a limited period. And, he added, ‘We should design for longevity. We should maximise the service life of components, reduce gaps and joints and systems and increase the longevity of glass facades.’

All this may sound hard, but Kennedy ended by saying that as well as driving change and pushing boundaries, the industry should celebrate success. ‘This will make your business more competitive. As a business, you will achieve more first-mover advantage.’

Daniel Doran, principal consultant with environmental consultancy Circular Ecology, explained why consideration of embodied carbon is so important. While the building and construction sector accounts for around 39 per cent of global energy and process-related CO2 emissions, the manufacture of buildings, materials and products by itself accounts for 11 per cent.

And, he warned, although individual buildings are becoming less hungry, the total contribution that construction makes is increasing with economic growth. In order to really understand what is happening on an individual building, Doran stressed the importance of EPDs (environmental product declarations). These will inform the user of all the environmental impacts from a product, including carbon.

Just because a product or a range of products has an EPD does not mean that it is good, he said. It is important to look at the figures. Calculating the carbon footprint of all the products in a building is evidently complex. Fortunately, said Doran, there are life-cycle assessment (LCA) tools available, ideally to be used with BIM.

For timber, he said, there is ‘particular consideration for biogenic or sequestered carbon’. This is the CO2 within the material that has been absorbed from the atmosphere while it was growing, and will remain locked-in until it is destroyed or decomposes. LCAs will recognise this sequestered carbon, as long as the trees come from a sustainable source and will report a negative CO2 value at the product and construction stage.

However, Doran warned, this benefit will be put back as a load at the end of the building’s life. This will be the case even if the timber is to be re-used in another building, since it is the new building that will benefit, and it is important to avoid double accounting.

He also warned against over-specification – putting more timber than is needed into a building to make the initial figures look better. All resources are scarce, and other projects may be forced by shortage to use less sustainable materials. Instead, he argued, it is important to avoid over-design and wilful design, to design for product re-use by using mechanical fixings rather than bonding, and where possible to use common modules.

Roly Ward, national account manager for Medite Smartply, explained his company’s approach to sustainability, a mixture of the will to achieve this, certification and measurement. So, for example, the company generates 75 per cent of its energy by burning waste from its wood products. All its timber is FSC or PEFC certified. Its products have no added formaldehyde in order to maximise indoor air quality.

The company has EPDs for its products which are independently verified and, as Ward said, ‘eliminates greenwashing’. It is actively transitioning to zero-carbon manufacture. And, perhaps most important of all from the point of view of the specifier, ‘Product choice does not have to be made with a compromise of performance or quality.’

The timber-framed, zero-carbon COP26 House developed by Beyond Zero Homes

One architect that has specified Smartply is Roderick James Architects, which is using it for the COP26 zero-carbon house that it has designed to be in Glasgow during the climate conference. Peter Smith, architect and Passivhaus designer at the practice, explained that it has adapted the smallest of its standard houses, the Barn House.

‘We looked at every piece to see how we could reduce the embodied carbon,’ he said. ‘We went round the country asking various suppliers to come on board and provide their products and expertise. Most jumped at the chance.’ He added, ‘At the point of practical completion, we will have only emitted 25 tonnes of CO2, and have sequestered 50 tonnes.’ At the end of COP26 the house will be dismantled and moved to Aviemore to its permanent location as the first in a small development of 12 affordable houses.

These lessons, ranging from the general to the specific, show just how much can be achieved with goodwill, imagination, measurement, and data.