The Building Safety Act and Gateway 2 approval process for higher-risk buildings (HRBs) are driving higher standards across the construction industry, with architects and specifiers under increasing pressure to deliver safe, fully coordinated building designs. One area of particular complexity is the interface between masonry support systems and cavity fire barriers, where fire resistance and structural integrity must align without compromise.

Leviat has responded to this challenge with a collaborative and pragmatic approach, working closely with leading fire barrier manufacturers to ensure its Ancon masonry support systems can be integrated seamlessly across a wide range of applications. The objective is to support safety and compliance while maintaining flexibility in specification.

Central to this approach is the principle of designing support systems that work with standard fire barrier products, not against them. Rather than requiring bespoke solutions, Leviat develops details that allow contractors to use existing, tested fire barriers in typical structural and fire interfaces. This ensures compliance with fire performance requirements while supporting practical, buildable outcomes on site.

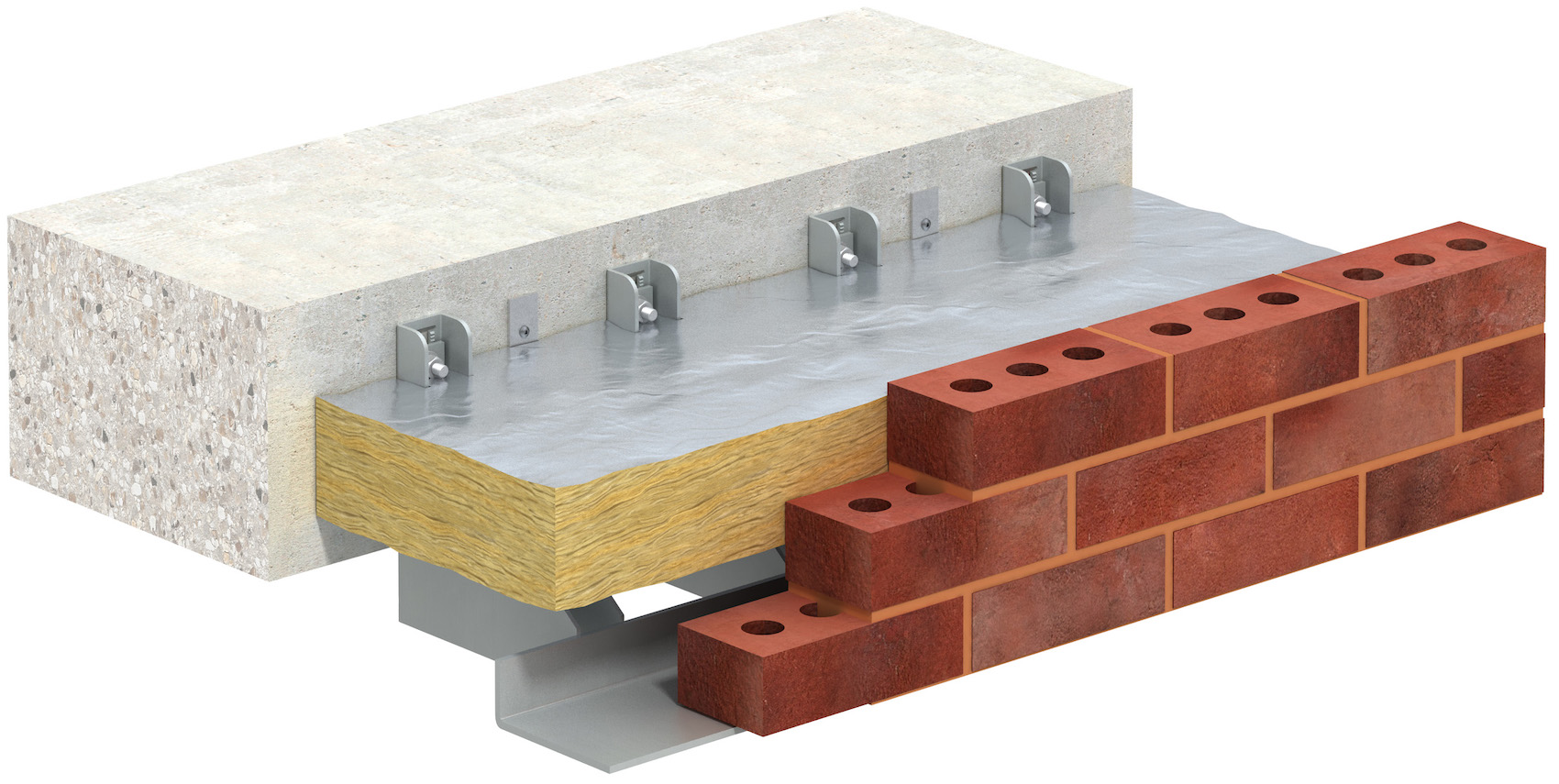

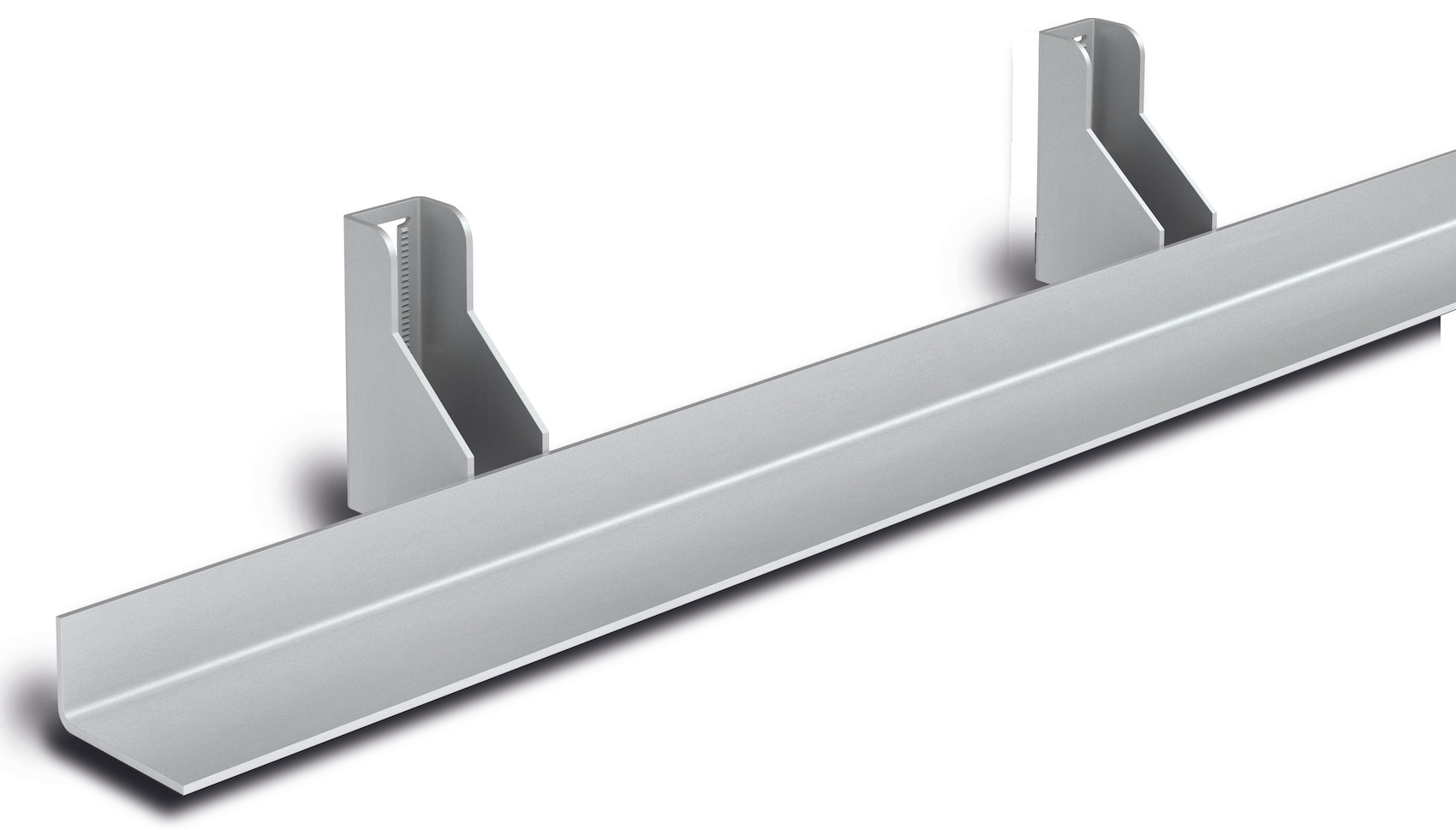

Careful consideration is given to the location and geometry of masonry support brackets in relation to fire barrier placement. Tolerances are managed to minimise or eliminate penetration into the barrier zone, helping to preserve the integrity of the fire barrier. In most cases, this involves designing bracket configurations to maintain the minimum required depth of fire-resistant material around penetrations, often 35mm or more, depending on the requirement.

Complex junctions

The design challenges become more pronounced at corners, balcony connections and complex junctions, where increased loads or varied geometries can result in bracket arrangements that would otherwise clash with cavity barrier placement. In these situations, Leviat works early in the design stage with specifiers and contractors to agree on workable solutions, such as upstand or downstand support configurations that accommodate both fire and structural requirements.

With different fire barrier products offering varying depths, fixing methods and test data, Leviat tailors its detailing to suit both the specific project and the chosen fire protection system. Multiple manufacturers are supported and the company frequently works with market leaders, such as Siderise, ARC Building Solutions and AIM, reflecting the high proportion of high-rise residential schemes where these systems are used.

To support specifiers further, Leviat is developing comprehensive guidance and CPD content in partnership with fire protection manufacturers, offering insight into interface conditions and detailing best practice. Combined with physical fire testing, third-party certification and fields of application reports, this guidance equips design teams with the confidence to make informed, compliant and cost-effective decisions.

Photo: Barratt London

Bermondsey Heights

One example of this in practice is Bermondsey Heights, a 26-storey residential development in Southwark, delivered by Barratt London. Leviat worked closely with the project team and cavity barrier manufacturer, Siderise, to design a support detail that avoided unnecessary bracket penetration into the fire zone. This involved refining bracket geometry, conducting test-based reviews, and providing clear installation guidance that aligned with both structural and fire safety requirements. The result was a compliant, well-considered solution that reflects the principles now embedded in Gateway 2 requirements.

Bermondsey Heights

One example of this in practice is Bermondsey Heights, a 26-storey residential development in Southwark, delivered by Barratt London. Leviat worked closely with the project team and cavity barrier manufacturer, Siderise, to design a support detail that avoided unnecessary bracket penetration into the fire zone. This involved refining bracket geometry, conducting test-based reviews, and providing clear installation guidance that aligned with both structural and fire safety requirements. The result was a compliant, well-considered solution that reflects the principles now embedded in Gateway 2 requirements.

By integrating fire safety into the design process from the outset, Leviat ensures its products contribute to a compliant, coordinated façade solution, one that meets today’s regulatory demands without restricting architectural freedom.

To find out more about Masonry Support Systems and Fire Protection Cavity Barriers, download the white paper.