In the first of a regular series, Jonathan Lowy from VMZinc answers readers’ questions on zinc.

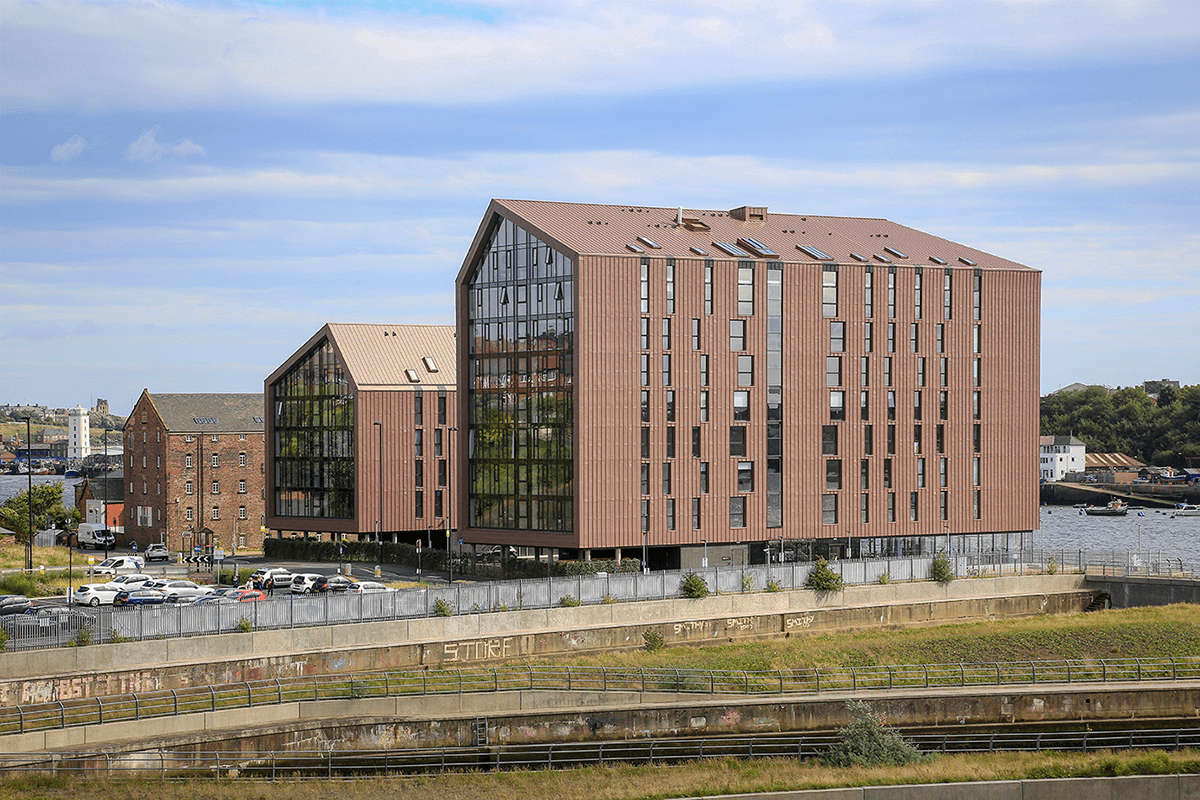

Weathered red zinc cladding on SimpsonHaugh’s Smokehouses residential scheme at Smith’s Dock shipyard in North Shields offers protection from the harsh weather conditions and gives a nod to the site’s industrial past.Credit: VM Zinc.

I keep getting asked by clients: why zinc as opposed to any other roof. What’s the one sentence answer?

There are many reasons including durability, recyclability and low maintenance but I’d say the big reason is visual appearance. It’s an attractive material whether it’s used on a roof or a facade. The fact that it’s not painted means that zinc – especially pre-patinated zinc – offers a warm, vibrant aesthetic that painted surfaces just cannot match.

What about durability? How long will a zinc roof typically last?

When correctly designed and installed, a zinc roof can last in excess of 100 years. The BRE Environmental Product Declaration states 100 years. Typically, zinc sheets corrode at approximately 2 microns per year and the thinnest zinc sheets sold for roofing in the UK are 700 microns thick. In a few very severe industrial and marine environments this corrosion rate can increase to 5 or 6 microns. Therefore occasionally the expected life span could drop to 60 years. Liverpool Central Library was fitted with a zinc roof in 1879. At this time the area was extremely polluted – and obviously coastal –and yet the zinc was only replaced in 2012!

How do you maintain a zinc roof?

The best way of maintaining a zinc roof is simply to let the rain rain over it and that is it. It is obviously good practice to clear out gutters at the end of the autumn and the occasional visual inspection would not go amiss but no other regular cleaning with special products is advised.

Can zinc be recycled at the end of its life?

VMZinc is 100% recyclable and in western Europe approximately 99% of zinc roofs and walls are indeed recycled, even if you might have to wait a long time to do it. This recycled zinc is then used for many things: galvanising, brass production, cosmetics and obviously new zinc sheets.

Can zinc be used on super insulated roofs?

Over the past 25 years, non-vented warm roof buildups have become more and more popular. The fully supported Aludex Max vapour and air barrier greatly increases air tightness and the insulation installed over this barrier is continuous with very few thermal bridges, thus further increasing thermal performance. The structural roof also carries a BBA certificate.

Is zinc appropriate for use on buildings outside Europe with very different climates?

VMZinc started to sell zinc to many countries around the world in the middle of the 19th century and this has continued into the 21st century. We have offices in many parts of the world and work regularly with local architects and installers.

A webinar, Around the World in Eighty Zinc Projects, is available at: www.youtube.com/watch?v=0B_DiXNNvPQ

Can zinc be used for gutters, downpipes or other roofing materials?

It can. Since VMZinc started rolling zinc in 1837 – and even before – zinc has been used widely as material for gutters, downpipes and flashings on tile and slate roofs. Indeed Anthra-Zinc was initially launched in 1978 as a flashing material to complement slate roofs.

How does zinc perform with regards to fire?

As zinc is a metal it is non combustible, A1 following EN13501. By adding a coating, which is the case with backside protected VMZinc Plus, the rating is A2. Both VMZinc cold, vented and warm, non-vented roofs have passed BROOFt4 flame penetration and spread tests.

What is the cost of a zinc roof or wall?

Generally the supplied and fitted cost of a zinc roof or wall will depend on three factors; location, complexity and size. Most supplied and fitted prices for zinc roofs and walls including flashings, trim, clips, etc but not substrates will be between £100-200/m².

What warranties are offered on zinc?

As VMZinc has been used as a roofing material since 1837 we have an excellent understanding of the durability of the material. We can now offer a material warranty of up to 50 years on a project by project basis. It is obviously critical that the zinc roof or wall is designed and installed correctly. Traditional standing seam roofing and cladding should be installed by a recognised hard metal roofing contractor and not by a general builder. VMZinc does have a partnership programme called VMZinc@Work. Partner members have extended experience with an excellent track record of installing zinc as well as following training sessions offered by VMZinc.

Call 0203 445 5640I or email vmzinc.uk@ vmbuildingsolutions.com for further information including warranty details, samples or online

RIBA accredited CPD