A potentially catastrophic blaze, which consumed the garage containing a parked vehicle adjoining a £1m house in rural Surrey, was stopped in its tracks thanks to the use of 12mm, A1 non-combustible Magply. The property was constructed using a structurally insulated panel (SIP) system with A1 non-combustible Magply used on the exterior of the building as the substrate panel for the proprietary render system.

Magply is a multi-use A1 non-combustible board with impressive fire performance in the offsite and timber-frame sector. The board is designed and specified to contain fire and support the emergency services with added crucial time. Although the emergency services were quick to attend the fire, it had taken sufficient hold that the large timber-framed garage was totally destroyed with just some sections of the frame still standing. However, the gable end to the house, which features a relatively thin weatherproof finish of the silica-based K-Rend suffered only surface damage. Remarkably, although areas of the render had spalled off, the 12mm Magply boards underneath had not even charred, while they had fully protected the SIPs structure beneath: a fact borne out by the system supplier, Glosford SIPs, which took core samples to confirm the continued integrity of the insulated sandwich panels which are faced by OSB.

“The fire-resistant qualities of the Magply boards saved the day,” commented Contracts Manager at Fullers Plastering, James Corlet. “We had utilised Magply as a render-backer on a number of projects before being awarded the contract to apply K-Rend to the half dozen homes here, and have always been very pleased with the performance. It is an easy board to cut and fix, and we can now definitely confirm to clients that it fully complies with the fire requirements for domestic and commercial buildings.”

“The Magply boards stood up extremely well: although the K-Rend which took the full brunt of the heat cannot be easily removed,” confirmed the homeowner. “So, though the Magply base boards did an absolutely first-class job they are going to be replaced as a precaution before the gable end wall is re-rendered. We hope the repairs will only take eight weeks to complete – mainly down to the lead time for a couple of replacement windows to be delivered.”

Fullers Plastering is based in nearby Brighton and is an approved applicator for a variety of render systems, whose manufacturers correspondingly recognise Magply as being a suitable substrate or carrier. In this case, credit must be given to James Corlett for requesting John Malone National sales manager of IPP/MAGPLY to attend the contract prior to construction to discuss the use of Magply as a render substrate board. In this case Magply was not part of the fire protection build-up, however the company over performed and made the difference when needed.

Magply board is BBA certified and tested with the leading testing houses in the UK, and testing is an ongoing process ensuring our board is tested to the stringent levels required. Magply is an magnesium Oxysulphate board and day-to-day we do get asked questions regarding MgO board. As a business, we never want to see our board perform in real life fire situations, however it happens and thankfully Magply has done its job in this case and a lesser board may not have performed in the same way.

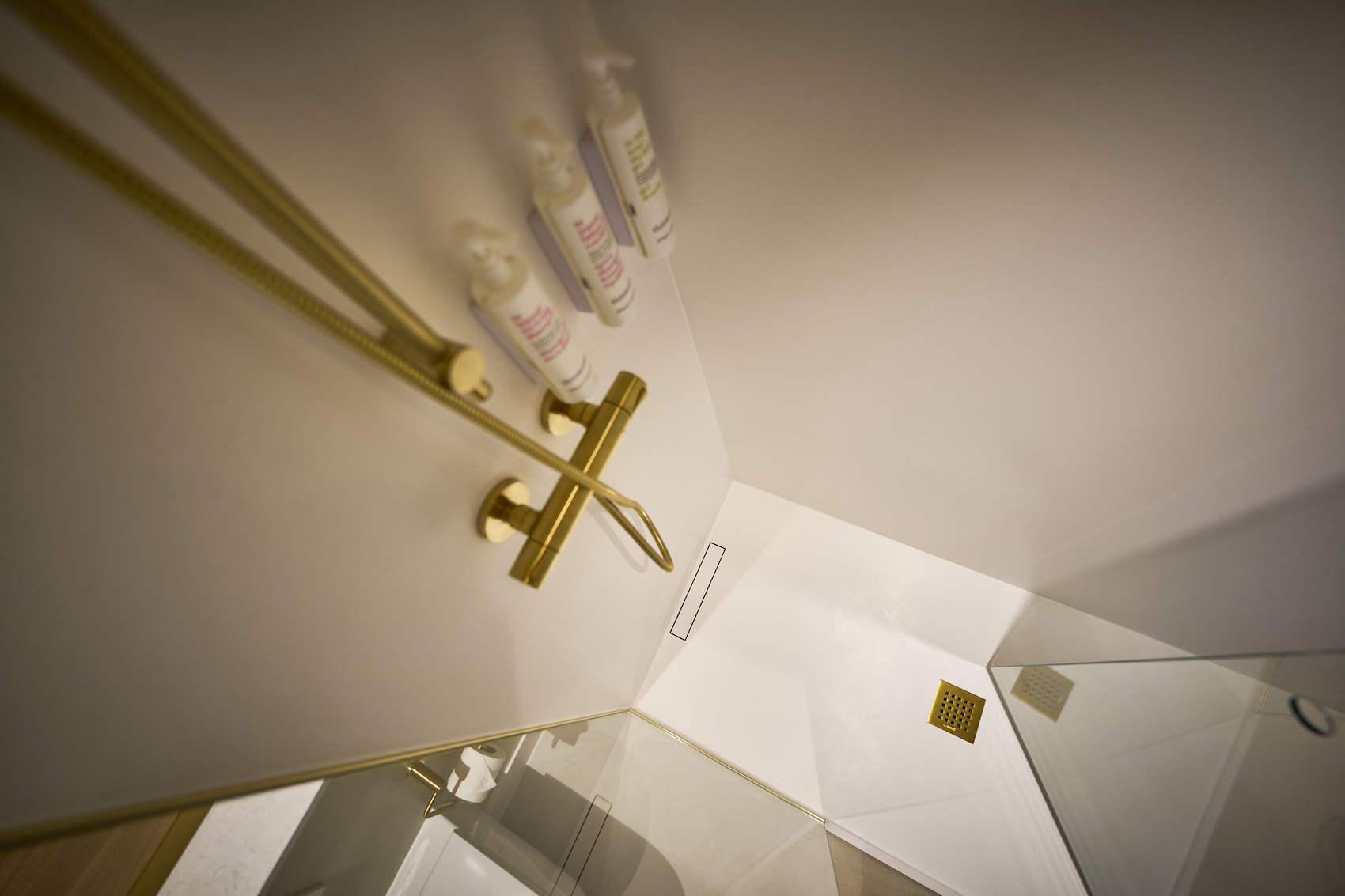

For more information on Magply board, we have a nationwide sales team in the UK and Ireland, and our board is available across the UK and Ireland. Magply is widely specified across the industry from modular to timber frame construction. The board is also specified as part of the build-up for cladding systems on high-rise properties, as well as pattress boards to carry bathroom or kitchen fittings.