Narinder Bassi, Group Product Champion at James Latham, speaks to Architecture Today’s Technical Editor John Ramshaw about the composition, performance and design potential of Valchromat MDF panels.

In association with![]()

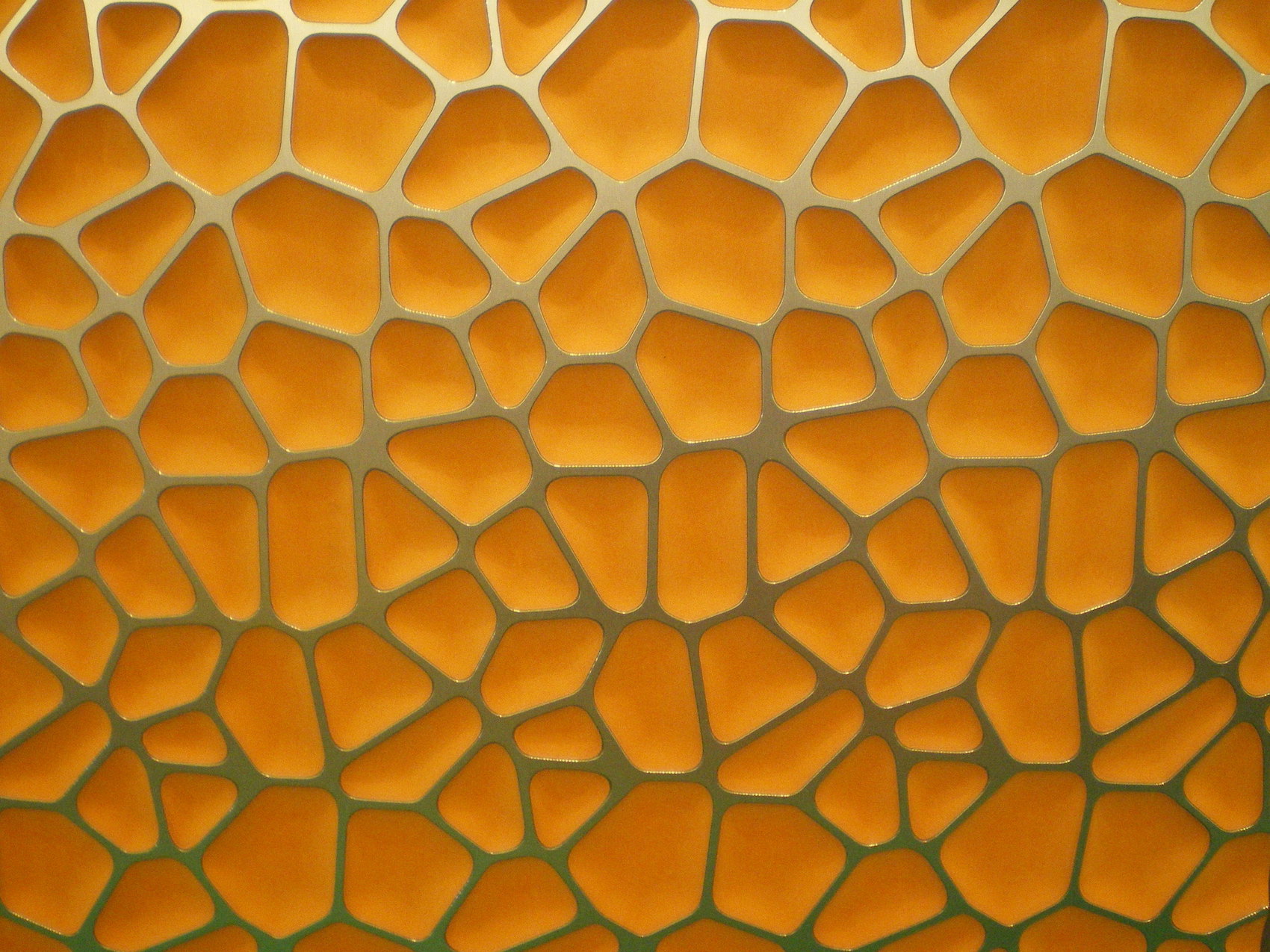

Faceted wall panel design (photo: Valchromat).

James Latham supplies one of the most extensive ranges of high-performance MDF panel products in the UK, supporting architects with solutions that are tailored to a wide range of applications and performance requirements. The collection includes lightweight boards for easy handling, fire-retardant and moisture-resistant grades, veneered finishes, and robust engineered products for exterior use.

Among the most popular, design-led and innovative options in the portfolio is Valchromat – a through-coloured MDF panel that combines structural integrity with high levels of workability and visual expressiveness. In conversation with Architecture Today’s Technical Editor John Ramshaw, Narinder Bassi, Group Product Champion for Valchromat at James Latham, discusses the manufacturing process, performance characteristics, sustainability credentials, and growing architectural applications of this versatile and aesthetically-pleasing material.

What is Valchromat, and how does it differ from standard MDF or coloured MDF alternatives?

Valchromat is a higher-density MDF that stands apart from standard MDF due to its enhanced structural integrity and through-colour composition. Unlike surface-painted or laminated MDF panels, Valchromat uses organic dyes to colour each individual fibre, resulting in consistent colour throughout the board. This allows for deep routing and edge detailing without exposing a discoloured core. Its density, machinability, and range of colour options make it ideal for both decorative and functional applications.

Red Valchromat bar at Catford Mews (photo: Cre8ive Joinery).

How is Valchromat manufactured, and what gives it its through-colour and unique structural characteristics?

Valchromat is produced from freshly harvested pine that is chipped, cooked and turned into wood fibre. During this process, organic colouring agents are added to the fibres, which are then chemically bonded using a specially formulated resin. This produces a board with exceptional internal bond strength, high density and homogenous colour throughout. The manufacturing process also contributes to Valchromat’s moisture resistance and machinability, making it particularly suitable for high-precision detailing and three-dimensional design work.

What are the key technical and aesthetic benefits of using Valchromat in architectural and interior design projects?

Valchromat combines technical performance with strong visual impact. In addition to being moisture resistant, it is structurally robust, and takes coatings exceptionally well. The latter allows architects to achieve matte, satin or tinted finishes using oils, waxes or varnishes. Valchromat has approximately 30 per cent higher density than standard MDF, providing excellent stability and reduced movement during cutting or shaping. This makes it a favourite among fabricators and joiners. Aesthetic consistency is maintained even when the material is routed, profiled or sanded, thanks to its through-colour composition. The material’s surface finish is exceptionally smooth, with no fibre breakout or ‘fluffiness’ during machining. Designers can explore both the surface and depth of the panel, making it ideal for layered applications, CNC machining, and creative forms that would not be possible with standard MDF.

Valchroma in the Wonderlab Gallery at London’s Science Museum (photo: Josh Cameron).

Is Valchromat suitable for use in high-humidity environments or for certain fire-rated applications?

Yes. Standard Valchromat is rated MDF-MR (moisture-resistant) and suitable for use in humid conditions, such as like bathrooms and commercial kitchens. However, it should not be used in areas exposed to direct water contact, such as countertops. A flame-retardant version is also available, certified to Class B-s2,d0, which inhibits the surface spread of flame and is ideal for public interiors and hospitality projects where enhanced fire performance is required.

What are the most common applications for Valchromat, and where is demand growing?

Valchromat is widely used in furniture design, wall and ceiling linings, retail and hospitality fit-outs, and exhibition stands. It’s particularly popular in commercial interiors where visual impact and durability are both priorities. Demand is growing in the kitchen and joinery sectors, where its moisture resistance and colour range make it a compelling alternative to traditional materials.

What colours, thicknesses and sheet sizes are available from James Latham?

We stock 12 Valchromat colours: White Grey, Light Grey, Grey, Black, Chocolate, Red, Yellow, Orange, Blue, Green Mint, Caqui and White Pearl. Available thicknesses include 8mm, 12mm, 16mm, 19mm and 30mm. Standard sheet sizes are 2440x1220mm and 3660x1220mm, with additional larger sizes available by special order. We are the largest Valchromat distributor in the UK, with common variants held in stock across our national depot network.

3D-routed yellow Valchromat panel (photo: Valchromat).

Can Valchromat be used structurally?

It is primarily a decorative panel, but it has sufficient structural performance to be used in furniture and cabinetry. It should not, however, be used in place of structural-grade materials like plywood or OSB where high loadbearing capacity is required.

What are the recommended fabrication techniques for Valchromat?

Valchromat is well suited to CNC machining, routing, sanding and edge profiling. The fibres are tightly bonded, preventing fraying and allowing for sharp, detailed work. Panels are factory-sanded (typically to 150 or 180 grit), but further surface preparation may be required before finishing. Laying out panels from the same batch prior to installation is recommended to reduce visible tonal variation. Edges should be treated and sanded using the same approach as surfaces.

Does the material require sealing or finishing, and what types of surface treatments are recommended?

Valchromat can be left unfinished for certain applications, but sealing is generally recommended to prevent staining and enhance durability. A range of waterborne or solvent-based finishes can be applied, including oils, waxes and varnishes. The Koate finishing system has been tested extensively with Valchromat and provides options to darken, lighten or alter the sheen of each colour without compromising clarity or performance.

Valchromat parquetry by Benjamin Scott at Rycotwood College (photo: Josh Cameron).

What sustainability credentials does Valchromat carry?

Valchromat is manufactured using FSC- or PEFC-certified wood sourced from controlled and responsibly-managed forests. It contains recycled wood fibre and waste material that would otherwise go unused, and it carries an Environmental Product Declaration (EPD). It complies with E1 formaldehyde emission standards and is also available in E05 and CARB II / TSCA IV-compliant formats. BREEAM attestations and ISO 9001 certification are also in place.

What technical support does James Latham provide to architects looking to specify Valchromat?

James Latham has a dedicated national Specification Team with appointed Valchromat Champions in every regional depot. Valchromat is our most requested sample material, and comprehensive technical support is available, including sustainability documentation, fire-rating data, safety data sheets, installation guides and loading tables. Additional digital resources and project consultation are available via James Latham’s website and showrooms.

What advice would you give to designers or fabricators working with Valchromat for the first time?

Think in three dimensions! Valchromat isn’t just a flat panel – it’s through-colour composition and machinability allow you to explore depth, layering and form in ways that traditional MDF or laminates can’t match. Colour layering or surface profiling can be employed to reveal visual effects. Designers should also consider the material’s strength, moisture-resistance, and machinability, while fabricators can leverage its ease of cutting, routing, and finishing. With the right tools and imagination, Valchromat opens up creative opportunities for furniture and interiors that are both functional and expressive.

Contact Details

To find out more about Valchromat, please email or visit the James Latham website.