Identifying the exposure rating of any site and changes following the application of BS 8104 has for years been an essential preliminary. There are however accompanying considerations in accessing buildings of all types, shapes and wall finishes, to ensure the intended performance of the building envelope is secured.

The objective is to design with long-term integrity against damp penetration. Note the saturated gable end compared with the return elevation in the photo below. The building is in a low exposure area but in reality the walls suffer wet penetration to a far greater extent than is witnessed on many ‘high exposure’ sites. The local conditions/topography are such that masonry saturation point is rapidly reached when wind accompanies rain.

In this instance the walling material is cement-based, and considerable water volumes run down the inside face of the exterior skin. If at critical intersections DPC measures are inadequate for a ‘high exposure’ scenario, problems can be anticipated.

Identical structures on a site will behave differently during weather conditions. If you incorporate a level of protection that will work regardless of the site exposure categorisation, you are providing protection for the worst scenario. In contrast, reliance placed on a system that promises anything less than ‘high exposure’ protection must prompt the question of whether the arrangement will always be adequate for your building?

Sensibly the objective must be to design and construct to one standard only, regardless of location and exposure rating. One that always works.

Gable abutments can perform adequately for years but then be overwhelmed when rain is accompanied with severe wind. The reason wet ingress is suddenly visible is because such gables feature running stepped flashings. This traditional single-plane arrangement accepts wind-driven rain can be blown and therefore permeate under each stepped leading edge.

Once the rain is just a few millimeters under the edge of a running flashing, it is in contact with the back of that flashing and the brickwork that is meant to be kept dry. This creates a damp permeating area, but one that is normally relatively small and out of sight.

Severe wind-driven rain – storm conditions – will to a greater extent, drive rain into and under running flashings. This commonly culminates in the permeating area expanding and gravitating, evidencing inside the building. Above the sloping roof the masonry is an outside skin, but below the roof it becomes an inside skin – now a damp one.

If the external skin of brick or whatever masonry type deployed has rough, uneven or an undulating finish, wind-driven rain entry is even easier.

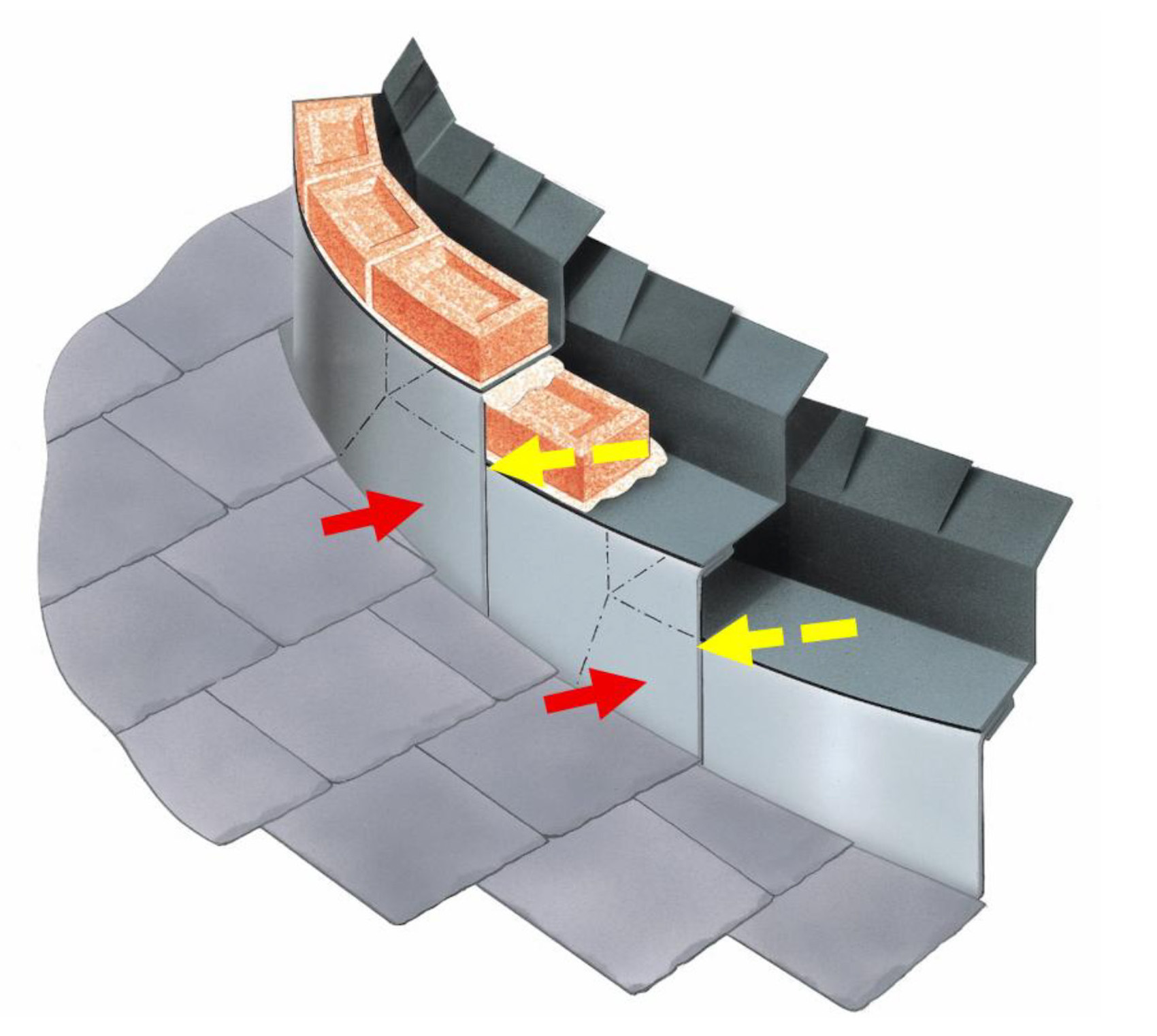

Using a UK and European Approved Cavitray eliminates this scenario. The Type X Cavitray manufactured by Cavity Trays Ltd is a preformed self-adjustable (to suit whatever cavity width is encountered) tray with its own shaped lead flashing already bonded on. Bonded-on means there is no on-site raking-out of mortar, no cutting and wedging-in of a running flashing, and no returning to site to point-in. The possibility of inadequate on-site linking does not arise.

Importantly, unlike a running flashing, the Type X attached flashing creates an overlapping configuration arresting rain and blocking the gravitational and lateral permeation path both in the masonry and via the flashing back (see dotted lines in the illustration below).

Whether the walls are straight, concave or convex, approved Type X Cavitrays are available for remedial as well as new-build applications. The Yeovil-based company manufactures more than 200 tray types, the majority with extensive permutation options. A bespoke service is also operating.

Cavity Trays

enquiries@cavitytrays.co.uk

www.cavitytrays.co.uk