Paul Morson, Group Melamine Manager at James Latham, speaks to Architecture Today’s Technical Editor John Ramshaw about Cleaf, a range of Italian-made melamines, laminates and matching ABS edgings that combine aesthetic performance with advanced surface engineering and dimensional stability.

In association with![]()

Cleaf Riga FB79 is a satin stone-effect finish with a length-oriented grain and antibacterial properties.

James Latham’s decorative panel portfolio includes some of the most technically- sophisticated surfacing solutions available to UK and Irish specifiers. Made in Italy, the Cleaf range of melamines, laminates and matching ABS edgings represent a step-change in engineered surface design – pairing high-resolution decorative layers with deeply embossed textures and robust substrates. Suitable for a wide range of interior applications, the panels are noted for their precision manufacturing tolerances, consistent finish quality and strong material resilience. In conversation with Architecture Today’s Technical Editor John Ramshaw, Paul Morson, Group Melamine Manager at James Latham, discusses how Cleaf panels are produced, what distinguishes them from standard melamine and laminate products, and how their outstanding aesthetic and technical properties support demanding and diverse interior schemes across multiple sectors.

Who manufactures the Cleaf range, and how are the panels made?

Cleaf is a family-owned company based on the outskirts of Monza in northern Italy. Founded in 1975 and celebrating its 50th anniversary this year, it has grown into one of the most advanced surface material manufacturers in Europe. Its panels use either MDF or chipboard cores and are faced with decorative papers using a bespoke melamine pressing process. Unlike standard melamine, the core board is layered with varying layers of Kraft paper dependent on the depth of texture required, and the panel remains in the press for significantly longer to ensure accurate pressure transfer and bonding – particularly for deep-embossed textures. This combination of longer pressing times and engineered Kraft paper layers ensures dimensional stability, surface fidelity, and long-term durability.

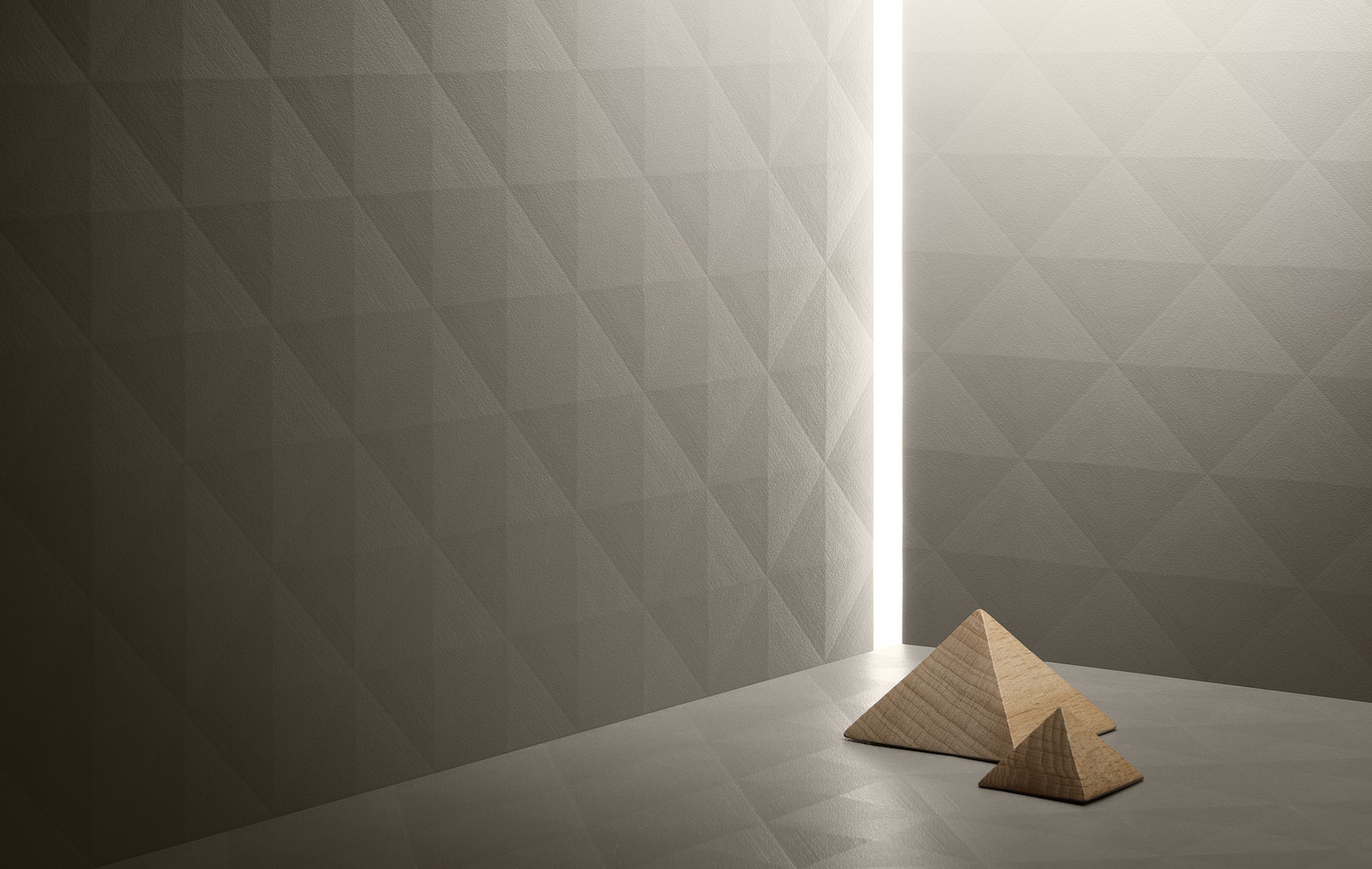

Cleaf’s Cheope is a geometric texture inspired by the perfect lines of pyramids seen from a zenithal point of view.

What makes the Cleaf collection stand out compared to standard melamine-faced boards or laminates?

It comes down to the depth, precision and realism of the surface textures, as well as a vast and curated decorative offering. Cleaf panels are designed to replicate natural materials, such as wood, stone, metal, leather and textiles, not just visually, but also to the touch. The level of detail is exceptional; it’s not just a visual trick. When you run your hand across a stone-effect surface, it feels realistic like stone; leather effects have tactile grain and warmth; woodgrains offer deep structures leaving a timber-like feel and metal finishes include embedded flecks that catch the light.

How does Cleaf achieve this level of tactility?

It’s achieved through the precise coupling of texture and decoration, supported by advanced plate-pressing and rotogravure printing technologies. The result is a surface that delivers depth, grain, shadow and material fidelity in a way that tricks the eye but satisfies the fingertips. It’s no exaggeration to say that these surfaces invite interaction; they’re engineered to be seen and felt.

What surface finishes and textures are available within the Cleaf range?

There are more than 60 individual textures in the Cleaf portfolio, from natural woodgrains and textile weaves to leathers, brushed metals, silks, marble and concrete. These textures can be paired with some 600 decorative papers, which allows for more than 36,000 possible combinations! Finishes range from deep tactile woodgrains to subtle linens and smooth mattes, and Cleaf’s Synchro technology aligns the embossed texture with the printed decorative layer for maximum realism. It’s a genuinely multisensory surface solution that designers can use to achieve a high-end look and feel across a wide variety of applications.

Penelope by Cleaf is a visually-striking linen effect.

What are the most popular decors or finishes currently being specified?

It depends on the sector, but textile-inspired finishes, such as Ametis, which resembles a spun-silk weave, and metal-effect Reflex are proving especially popular. They are currently being used in high-specification residential developments and hotel fit-outs across London. Woodgrain finishes like Quercia, a realistic oak effect, also remain in strong demand. The appetite for deeper textures and tactile effects, particularly those mimicking luxury materials, is growing rapidly across all markets.

Can specifiers create bespoke textures or colourways?

The stocked range at Latham depots consists of more than 100 finishes, however Cleaf also offers a bespoke service for larger projects, with a minimum order quantity of just 40 sheets. This enables architects and designers to develop unique decor and texture combinations outside the standard range. The company’s ability to prototype at speed is exceptional. We’ve seen requests realised in less than 24 hours, with samples fresh from the factory floor.

What performance characteristics do Cleaf panels provide in terms of durability, scratch resistance, and UV stability?

Cleaf panels are highly durable and resistant to scratching, impact and UV discolouration. Surface ratings are consistently at the top end of the performance scale, with abrasion and scratch resistance rated at ≥4 on the EN 438 scale. This makes them suitable for demanding vertical and low-impact horizontal applications in residential, commercial and hospitality settings. The melamine and laminate surfaces maintain their colour and finish quality over time, even in high-use environments with prolonged exposure to light.

Cleaf’s Primofiore texture is inspired by the grain, softness and ‘silkiness’ of leather.

Are the panels suitable for horizontal as well as vertical applications?

Yes. While Cleaf melamine-faced boards are typically used vertically for wall panels, cupboard doors or partitions in low-to-medium traffic areas, matching laminates are available for horizontal applications, such as worktops, desktops and counters and vertically in high-traffic areas. The seamless integration of matching ABS edgings across both product types ensures visual consistency and design continuity across interior schemes.

Could you tell me more about Cleaf supporting components?

Every Cleaf decor is available with matching ABS edgings and, where required, laminates. This makes it easy to deliver a cohesive look across different surfaces and applications. ABS edging is available in multiple widths, and the precision of the decor match ensures that grain alignment, colour tone and finish are maintained across the final installation. The 1mm thickness also allows the edgings to go practically unnoticed.

In what settings are Cleaf panels most commonly used, and where is demand growing?

Cleaf panels are used across a wide range of sectors, including high-end residential, retail, hospitality, education and healthcare. We’re currently seeing significant growth in the shopfitting and hospitality markets, where designers are looking for premium surfaces that combine durability with luxury finishes. Cleaf panels are also increasingly used in large-scale build-to-rent and student accommodation developments, particularly for kitchens, wardrobes, reception areas and feature walls.

Event held at the Cleaf showroom in Clerkenwell, London

How do they perform in tough environments, such as hospitality, retail or healthcare?

The performance characteristics of Cleaf panels, including impact, scratch and UV resistance, make them ideal for demanding environments. Their dimensional stability ensures they stay true over time, even in areas subject to repeated cleaning or mechanical contact. We’ve supplied Cleaf panels for premium retail environments, changing rooms, hospitality receptions and healthcare facilities where aesthetics and hygiene go hand-in-hand.

What sustainability credentials do Cleaf panels carry and do they comply with UK indoor air quality and fire safety standards?

Cleaf products are FSC-certified and manufactured to CARB2 and E05 compliance, which means they meet rigorous international standards for formaldehyde emissions and indoor air qualityThe range also includes fire-rated panel options, made to Euroclass class B-s1,d0 EN13501. Added to this, the company’s longstanding environmental commitment is demonstrated through responsible sourcing and continuous innovation in low-emission manufacturing.

What support does James Latham offer to specifiers using Cleaf?

We provide full technical support, specification guidance, and sampling services (including half-A4 samples and Swatchboxes of our UK stocked range) through our national depot network and dedicated specification team. Showrooms in Hemel Hempstead and London’s Clerkenwell hold large-format Cleaf panels for clients to view and handle in person, which is essential given the tactile nature of the material. In addition, Latham’s Digital Showroom and 3D visualisation tools help specifiers explore the range virtually. Meanwhile, James Latham’s depot Product Champions, technical advisors, and dedicated specification team are on hand to assist with decor selection, availability, matching components and pricing. We also offer introductions to specialist fabricators if required.

Contact Details

To find out more about Cleaf, please email or visit the James Latham website.