Bennetts Associates’ Advanced Product Creation Centre for Jaguar Land Rover employs Europe’s largest timber roof

Jaguar Land Rover’s Advanced Product Creation Centre in Gaydon, Warwickshire, brings together design, engineering and production purchasing under one roof for the first time. Designed by Bennetts Associates with Buro Happold, the 50,000-square-metre facility accommodates 3,500 staff and is intended to encourage collaboration throughout the entire vehicle development process.

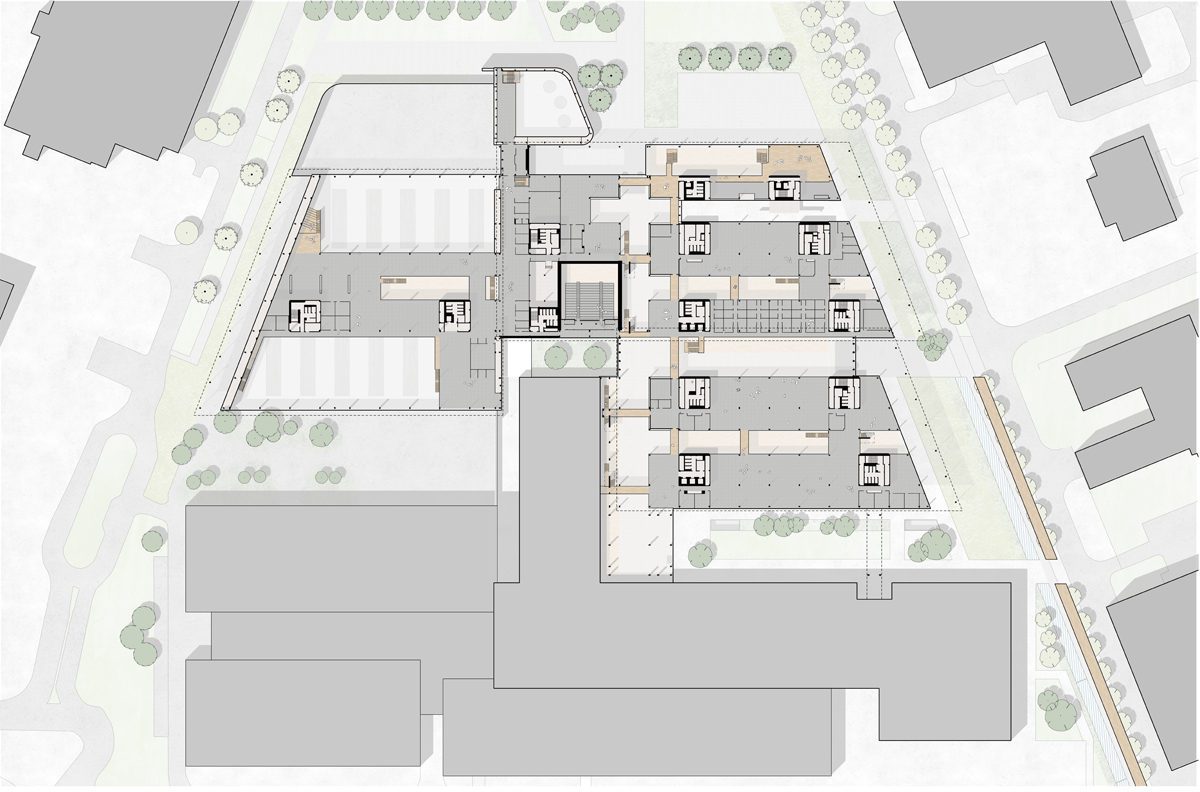

The brief was to consolidate operations for greater efficiency, help transform working practices, embed sustainability and wellbeing, expand facilities, and relocate Jaguar Design from its birthplace in Coventry to sit alongside its sister brand’s studio. Located on a former airbase, the four-storey scheme includes studio spaces, offices, a 400-seat multipurpose hall, restaurant, visitor building and other amenities. An internal ‘street’ connects the new facilities to existing buildings, maximising the potential for chance encounters between staff, which can in turn aid creativity, innovation and cross departmental synergy.

Ground, first, second and third-floor plans

Intended to expresses warmth and sustainability, the building is covered by what is said to be Europe’s largest timber roof. A structural steel ‘super-grid’ accommodates a wide range of internal spaces and correlates with the triangular geometry of the original airbase runways. Oversailing rooflights and glazed curtain-walling flood the interior with daylight. Natural ventilation is employed throughout the communal spaces.

The exterior landscape is intended to bring the beauty of the rural setting into the site, reinforcing the sense of place. A new lake articulates the arrival experience, and forms part of the sustainable drainage strategy. An existing car park has been transformed into a green park serving the site-wide community.

The project was delivered through novated Design & Build with Laing O’Rourke. Employing extensive Design for Manufacture and Assembly (DFMA) not only provided quality, efficiency and safety benefits, but also mirrored the nature of Jaguar Land Rover’s business, says the architect.

Additional Images

Credits

Architect

Bennetts Associates

Structural engineer

Buro Happold

Landscape

Grant Associates

Quantity surveyor

Thomas & Adamson