Aoibhín McGinley and Lauren Li Porter discuss how the practice’s expansive and carefully curated materials library infuses both its work and work-life with practicality and playfulness.

Associate directors Aoibhín McGinley and Lauren Li Porter pictured in the practice’s east London studio.

Manalo & White is an award-winning London-based practice that prides itself on its cohesive, diverse and talented design team. Through an enviably broad portfolio, including cultural, leisure, education and industrial projects, it has demonstrated an unwavering commitment to creating purposeful and inclusive architecture that prioritises users’ needs. But pragmatism is only part of the story, the work is also eye-catching and joyful – not least in terms of its material and colour choices. Practicality and playfulness are further interwoven through detailing rigour, resourcefulness, and the championing of humble materials, as associate directors Aoibhín McGinley and Lauren Li Porter explain.

Your expansive materials library occupies around the half the office. Why is it so prominent?

Aoibhín McGinley When we moved into this space during the Covid pandemic, we took the opportunity to expand our materials library, so that everything could be clearly laid out and celebrated. We were aiming for a ‘shopping’ experience! [laughs].

Lauren Li Porter The library was purposed designed by us for the space, and we were quite particular about the depth and number of shelves. It’s a shop display philosophy aimed at highlighting what is important and what we are interested in, rather than everything we’ve amassed. The temperature of the luminaires in the library was also specially chosen to give the most accurate colour rendering of the materials.

Aoibhín McGinley In terms of layout, the library encloses our main meeting space, and its proximity actually helps us solve design challenges. Clients can also see and get excited about the materials during meetings and design discussions. Organisationally, the resource is divided into specific sections including, masonry, timber, ceramics – we love a tile! [laughs] – and internal finishes. We’re very much a retrofit-first practice and do a lot of interior architecture. There is also a project-specific section that displays materials related to live projects.

Wood wool panels by Troldtekt. “The practice has used these simple but effective wood wool panels on the ceilings at iQ East Court. They’re a great alternative to traditional plasterboard, have a wonderful texture, and provide good acoustic performance.”

What drives material selection at the outset of your projects?

Aoibhín McGinley We typically develop an overall concept for a project, and as that gets refined the material language emerges from it. Everyone tries to keep up to date with new materials and there’s a lot of discussion during design development, so it’s relatively easy to develop the materials palette once the concept has been agreed. The practice particularly likes to celebrate and elevate relatively humble materials. We also avoid complicated detailing, so design elements can be easily disassembled and reused. Materials that are honest about what they are appeal to us, like brick and exposed timber elements.

Lauren Li Porter Many of our clients, including those in the student housing sector, tend to prioritise robust materials that age well and do not require constant maintenance. In terms of PBSA (purpose- built student accommodation) projects, clients often like to establish a recognisable ‘family’ of design and material elements across multiple schemes. As designers, we want to find variations within these families to keep projects fresh and engaging.

The practice is always looking at new and innovative ways of making spatial divisions within large floor plates – without recourse to full compartmentalisation. On iQ East Court, [student amenity space, London, 2024] we used GRP mesh decking to partition the space into distinct zones. The decking, which was originally intended for marine environments, is not only inexpensive, through-coloured and robust, but also carefully balances privacy and daylight penetration issues. We like to approach material selection with a little bit of humour, but without ever being cartoon-like.

Oil-stained plywood by Morrells. “A very simple but effective material is colour- stained plywood veneer. It really adds character and elevates the material’s status despite its low cost. It’s also quite fun!”

Aoibhín McGinley At TACO! [arts and culture hub, Thamesmead, 2023], we used Ketley bricks to form internal rooms and spatial divisions. While we like the robustness and durability of brick, we also chose it for its strong connection to the Thamesmead Estate, where residents often make small built interventions within their own flats and gardens. We’re constantly looking for something contextual that serves as a hook for the design concept.

How do you balance the competing desires for practicality and playfulness when it comes to material choices?

Lauren Li Porter There’s something fun about finding a material that is not particularly sexy, and then making it sing from a design point of view.

Aoibhín McGinley While some of the materials we specify are highly utilitarian, such as the GRP mesh, we’re always very specific about the colour we want and how they go together on site. Rigorous detailing requires a lot of effort, but that’s what elevates these materials and is part of the fun of adapting them to applications for which they were never intended. It creates a language that adds richness and coherence to our schemes.

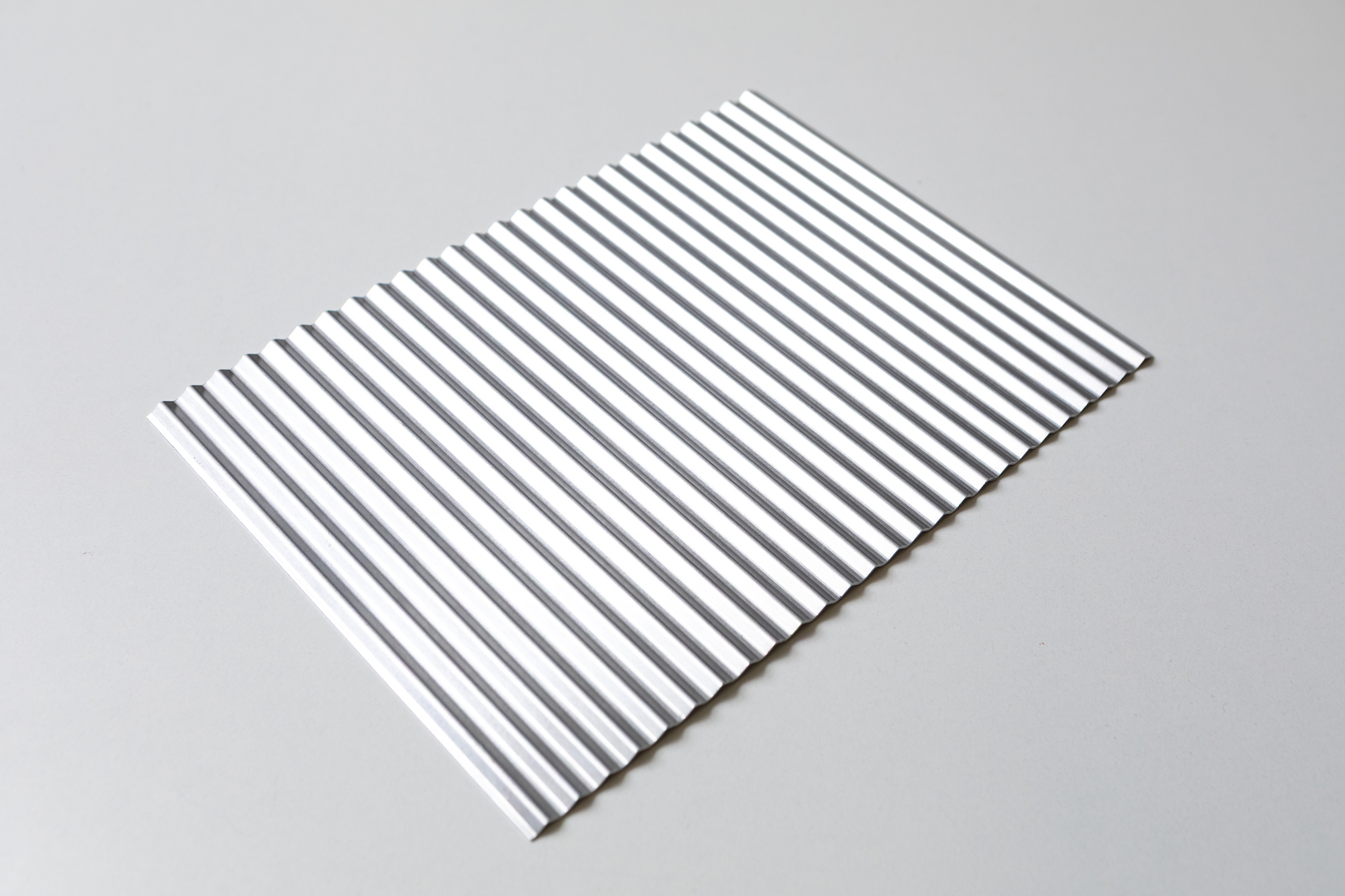

Fluted aluminium sheet by Cadisch MDA. “This forms part of the iQ Student master specification, and is typically used as a covering on lounge walls or front desks. We often use the sheeting with other fluted products, such as acoustic cork panels, to form part of the project’s overall design language. It is also highly recyclable if it’s left in its natural finish.”

Brian [Greathead, director of Manalo & White] has instilled in all of us the need to know the precise sizes that the materials we specify come in, with respect to detailing and drawing things accurately. It’s simply not good enough if the contractor has to ‘lop a bit off the end’ to make a material fit on site. It’s about having a proper respect for the material – whatever it is – in the first place.

Lauren Li Porter I think building users do notice these things, so it’s worth being bloody minded sometimes!

Inclusivity is a key aspect of your work. Are you able to extend this to, or represent it in, the materials you use?

Lauren Li Porter We find that if you try to exceed the basic requirements for colour contrast or textural changes in relation to inclusivity, there’s a huge opportunity to do something really interesting and fun.

Aoibhín McGinley We work with the DisOrdinary Architecture Project across a lot of our schemes. The organisation invites artists with specific disabilities, who it feels are appropriate to the project, to provide personal engagement on inclusivity – rather than it being a tick-box exercise. On Frân Wen, [performing arts centre, St Mary’s Church, Bangor, 2023] we worked with a local sound artist to develop an aural wayfinding strategy that drew its inspiration from the building’s church organ.

Staffordshire Blue brick by Ketley Brick. “We love the rich colour and patination of this brick range. It is available in both brick and paver format, which allowed us to specify it for the floors and partition walls of our TACO! arts project on the Thamesmead Estate in London.”

Lauren Li Porter Myself and Aoibhín worked on the East End Women’s Museum [refurbishment, London, unbuilt] whose mission was to make a new kind of museum that was welcoming to a broader audience. We talked a lot about using materials that would feel less institutional and more welcoming; borrowing ideas from domestic spaces, such as fabrics, tiling and colour-stained joinery items. The idea was that visitors would feel they had ‘permission’ to come in and use the spaces as they saw fit, and the displayed gallery information would form a backdrop, almost like wallpaper.

Your work frequently features bespoke design elements using both humble and higher-end materials. Do you work closely with manufacturers to develop these items?

Aoibhín McGinley Using humble materials resourcefully and imaginatively often allows us to spend a little more money on bespoke items within a project. A good example is the iQ student specification, where we worked with Domus to develop a series of ceramic tiles with rounded corners. They typically appear on feature reception desks, which occur across multiple projects in slightly different guises and colours.

Spolia by Solus Ceramics. “This is an innovative UK-made terrazzo that can incorporate project- specific waste into a bespoke tile. It’s a cost-effective and sustainable way of creating a beautiful flooring finish that we are hoping to use in the near future.”

Lauren Li Porter More recently, Brian [Greathead] has been working closely with New Terracotta to produce beautiful, bespoke-glazed tiles for a DJ desk in the Mandrake Hotel [retrofit, London, phased, 2018-present]. We visited New Terracotta’s factory as part of the development process, and were really impressed by their artisanal approach, which takes everything in-house.

Do you organise many factory visits?

Lauren Li Porter Yes, and they can take several different forms. With New Terracotta we specifically wanted to explore glazing variations in the bespoke tiles they were developing for us. We also wanted to know more about how they made their products, so we could use that knowledge in future projects. At the other end of the scale, we visit furniture suppliers at least once a year to look at new pieces. The practice is really particular about only specifying chairs or sofas that we’ve actually sat on. These items have to be comfortable and not just photograph well!

Aoibhín McGinley Yes, it’s a real bugbear with us, and we perform informal long-term tests on pieces in the office, looking at both comfort and durability.

Planed softwood timber. “Softwood – be it used for screens, panels or partitions – is one of the practice’s preferred interior materials. It appears on a lot of our projects and we’re particularly drawn to its multifunctional nature and honest aesthetic.”

Lauren Li Porter Our student accommodation projects have also led to factory visits with bathroom pod manufacturers. The quantities of units involved in these projects mean that even small design efficiencies can save huge amounts of money, as well as improve the usability of the modules. Investigating the pod in a factory environment with the client and other consultants is invaluable in terms of progressing the design and making efficiencies.

Colour often plays an important role in your projects. Are you drawn to materials that can help you facilitate this or are through-coloured?

Lauren Li Porter Through-coloured materials appeal to us in terms of minimising maintenance and future costs. But we also love colour for its own sake and the joy it can bring to projects. Specific items within the materials library, such as loose fabrics, are arranged by colour, and we often begin projects by doing a ‘material pull’. That is, pulling everything together in a big pile and looking at it alongside the project concept and context. Through our PBSA work, we’ve developed good relationships with a range of manufacturers, allowing us to colour- match key design elements or develop bespoke colourways.

Extruded terracotta blocks by Solus Ceramics. “These attractive lightweight blocks are ideal for interior screens. They not only provide good levels of privacy, but also allow plenty of daylight through, which is important in deep floor plans.”

Aoibhín McGinley We often start [projects] with the colour, and then we’ll draw things in from that, or maybe reference a tone we’ve found in a specific material. But there needs to be an underlying narrative or structure to colour choice; otherwise the choice is endless.

What materials have you found recently that interest you?

Aoibhín McGinley We’ve come across Spolia from Solus Ceramics, which is a terrazzo that can be made from project specific waste materials. Traditional terrazzo is an expensive item, so if you can make it from materials that already exist on site, it suddenly becomes more viable. We’ve not been able to use it yet, but we are keen to specify it in the future. Another recent discovery are beautiful faience tiles from HG Matthews. The colours are rich and the glazes have an attractive patina that looks like cake icing when viewed from the side!

Lauren Li Porter I’ve been wanting to use Woodio, a resin-bound, waste woodchip surface material which is made in Finland. It uses minimal water in its production. I believe the resin binder is vegetable-oil based and as a result the panels can be disposed of as energy waste or crushed and incorporated into cement, which makes the product more environmentally-friendly than some other alternatives on the market. It reminds me of Foresso timber terrazzo, and is slightly translucent when lit from behind, which adds to its visual appeal. We’re always looking for ‘frameable’ panel materials and this really fits the bill.

Bespoke ceramic tiles from Domus. “The square 100x100mm tile from Domus comes in a wide range of colours and is very budget- friendly. By paying a little bit more for bespoke curved and rounded edge pieces, we’ve been able to develop a unique design language that runs through and connects multiple PBSA projects for the same client.”

Do you find yourself returning to certain materials, and if so which ones and why?

Aoibhín McGinley Timber, or more specifically, softwood framing. You can just do so much with it. There are different section profiles, different proportions…it’s definitely one of our faves! Brick is another go-to material. Our work often incorporates extensions or alterations to existing buildings, where brick is the natural choice. The practice is currently working on a retrofit project in Clerkenwell, where we’re adding an additional floor and pitched roof to a former foundry building. The intention is to re-skin the building in brick and pigmented concrete with fair-faced blockwork and exposed timber used internally.

Do you organise materials-based CPDs?

Lauren Li Porter We do a lot of these and we also try to keep abreast of the latest product and material developments via the major design festivals. The practice also enjoys learning about materials from other architects and consultants. Matt Barnett Howland, who is a good friend of Brian [Greathead], recently came into the studio to talk through the design of his Stirling Prize-shortlisted Cork House. We’re a sociable office, so we’re always looking for things we can do as a group, which involve learning. And in a way that brings us back to the beginning, and how we chose to organise the library. The point is, we’ve tried to create a space that can also be used for socialising; for welcoming clients and friends; and hosting events. We didn’t want it to feel incidental.

Aoibhín McGinley [points to neon ‘Barry’s sign hanging at one end of the materials library] This was the result of a huge amount of discussion and is obviously a reference the practice name: Manalo & White! Part of its aim is to welcome clients and visitors into an exciting ‘behind the scenes’ space, that is both multifunctional and experiential. Special events we host here often have their own cocktails and playlists, so the space not only serves the practical ‘day-to-day’ needs of the office, but also its joyful ‘one-off’ occasions.