AccuRoof Trading Director Rob Edwards discusses the key performance and environmental benefits of the IKO Spectraplan® TPE single ply roofing membrane, with Architecture Today’s Technical Editor John Ramshaw.

In association with![]()

IKO Spectraplan® TPE roof covering at Stroud College in Gloucestershire (photo: courtesy of IKO).

Single ply is a popular, predominantly synthetic, polymer-based roofing membrane that can facilitate lightweight, flexible, and durable waterproofing solutions. AccuRoof’s ability to supply a broad range of single ply roofing solutions – alongside many other flat and pitched roof systems – means that it is ideally placed to offer expert, product-agnostic advice on both new-build and refurbishment projects. Together with PVC, one of the key products in its single ply offering is Spectraplan®, a TPE membrane manufactured by IKO. Rob Edwards, Trading Director at AccuRoof, in conversation with Architecture Today’s Technical Editor John Ramshaw, discusses the product’s technical and environmental characteristics and benefits.

What is a TPE membrane?

There are three main types of roof membrane: modified bitumen, thermoset, and thermoplastic. Polyvinyl chloride (PVC) and thermoplastic olefin (TPO) are among the most common compounds found in thermoplastic membranes. IKO Spectraplan® is a thermoplastic polyolefin elastomer or TPE, which makes it a member of the TPO family.

Spectraplan® membranes are manufactured at IKO’s state-of-the-art production facility in Chesterfield (photo: courtesy of IKO).

What is special about IKO Spectraplan® in terms of a TPE offering?

IKO Spectraplan® is the only TPE waterproofing membrane manufactured in the UK. It is only available in the UK from AccuRoof, and can only be installed by an AccuRoof Registered Roofing Contractor (ARRC). This can provide extra peace of mind for specifiers and their clients. Another benefit is that the membrane can be specified in combination with a wide range of complementary IKO accessories and fastening systems, including PIR insulation boards, mechanical attachments, prefabricated detailing elements, primers, adhesives, and cleaners. In other words, Spectraplan® can be specified as a complete roof system from a single manufacturer (IKO) and specification supply partner (AccuRoof).

The membrane itself is white and incorporates a reflective pigment to reduce heat retention. Following testing by an independent accredited lab – in accordance with ASTM C1371-04a, ASTM C1549-09, and ASTM E1980 – IKO Spectraplan® now achieves 91 on the Solar Reflectance Index (SRI scores range from 0-100). Using materials with higher SRI values provides a ranges of benefits, including cooler indoor temperatures and improved occupant comfort, lower cooling energy demands and emissions, a decrease in the urban heat island effect and extended roof lifespan through reduced heat-related wear¹.

Finally, no solvent preparation is required during Spectraplan® installation, and the membrane does not require harsh chemicals during routine maintenance – a mild soap solution applied with a soft broom, rubber wiper or pressure washer is all that is needed.

The white membrane achieves 91 on the Solar Reflectance Index (RFI), helping to reduce indoor temperatures and extend the lifespan of the roof through reduced heat-related wear (photo: courtesy of IKO).

Does Spectraplan® provide flexibility in terms of application and fixing methods?

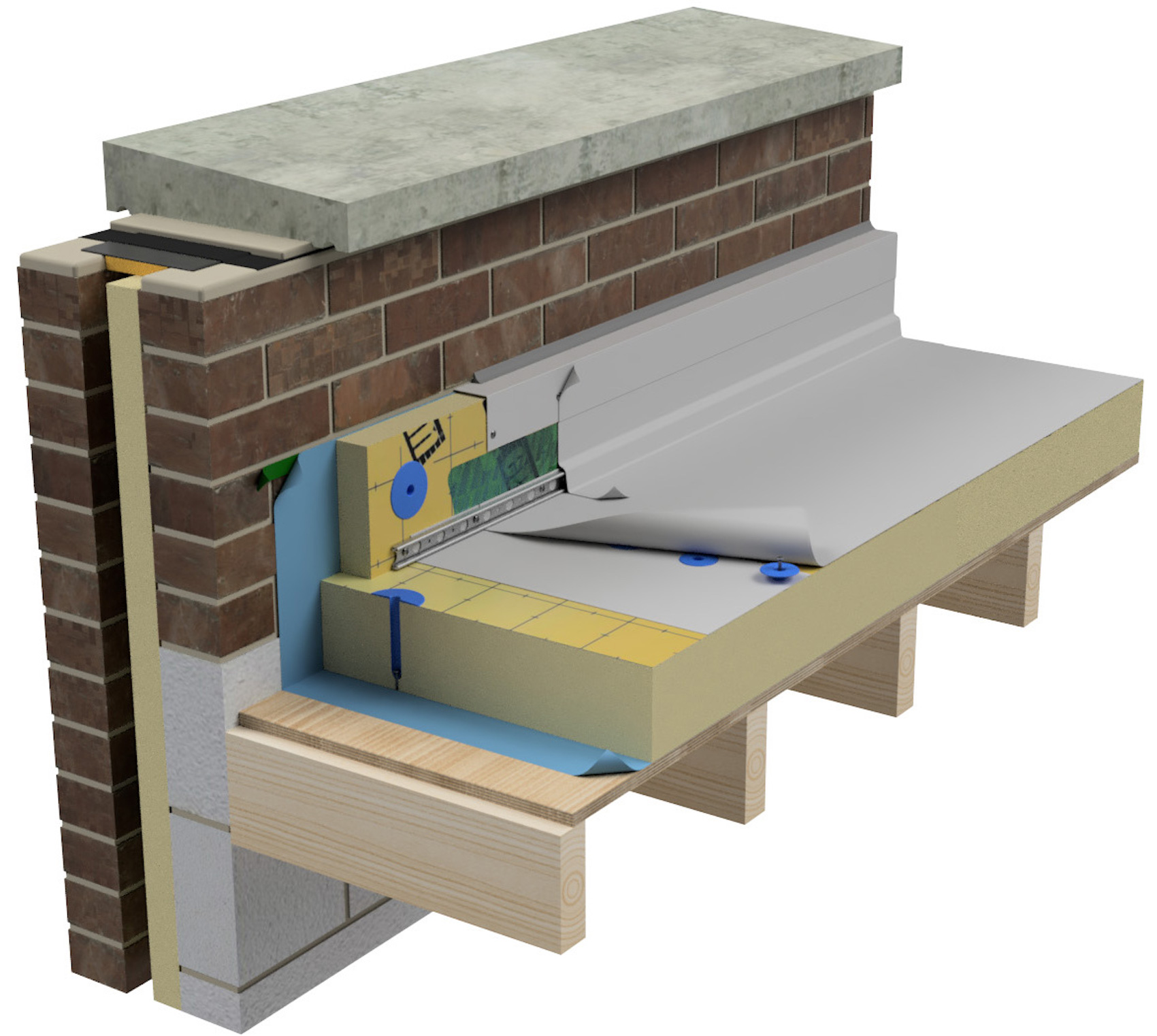

Yes, there are three product variants to choose from. IKO Spectraplan® SM is for mechanically-fastened roofing systems on both flat and pitched roofs. It can be installed over most substructures, including profiled steel and timber, and is suitable for new-build and refurbishment projects. The membrane is mechanically fastened in the overlap using IKOfix thermally-broken washers and IKOfix fixings into the deck, as well as hot air welded overlaps. IKO Spectraplan® SM can also be used for loose-laid and ballasted, and inverted roofs, adding to its versatility.

For adhered applications, there is IKO Spectraplan® SG, which is a glass tissue reinforced, polyester fleece-backed product. It can be adhered to most common substrates using Spectrabond Low Foaming PU adhesive or IKOpro Sprayfast FMA adhesive, and is again suitable for both new-build and refurbishment projects. Finally, there is IKO Spectraplan® D, which comprises two layers of TPE laminated together, and is intended for complex roofing details. Its flexibility makes it ideal for secure seam welding and intricate detailing. It’s important to mention, that IKO Spectraplan® TPE membranes are also compatible with existing bitumen membranes, without the need for a separation layer. Last but not least, there is Spectraplan’s wide welding window of 200-600°C.

IKO Spectraplan® roof build ups (left to right): mechanically fixed, ballasted, and fully adhered (drawings courtesy of IKO).

What backing does Spectraplan® have in terms of certification and warranties?

The Spectraplan® membrane is BBA-certified (certificate No. 05/4203), while Spectraplan® roof systems have been classified to achieve BROOF(t4) – in accordance with EN 13501-5 – to enable compliance with Part B of the Building Regulations. As I mentioned before, the Spectraplan® system through AccuRoof can only be installed by our ARRC operatives, and it comes with IKO material warranties of up to 25 years, alongside a BBA life expectancy of 30 years. AccuRoof can provide warranties of up to 25 years for complete Spectraplan® roof systems that it has specified and supplied.

Solvent preparation is not required during the installation of Spectraplan®, and the membrane has a wide welding window of 200-600°C (photo: courtesy of IKO).

What advice would you give architects looking to specify a Spectraplan® roof system?

Talk to us! AccuRoof provides a comprehensive specification service, including technical drawings, wind uplift, thermal calculations, and site support.

Contact Details

If you require design assistance on a roofing project, please call 01509 505 714, email, or visit the AccuRoof website.

¹ James, Patrick and Manfren, Massimiliano (2021) Future (p)roof: building resilience of the UK’s roofs for a changing climate. In, Building resilience of roofing technologies in a changing climate. Southampton. University of Southampton. (doi:10.5258/SOTON/P1079)