AccuRoof’s Technical Director Daniel Bosworth discusses the environmental and performance benefits of the IKO Permatec LI hot melt roofing system with Architecture Today’s Technical Editor John Ramshaw.

IKO Permatec LI was specified for the Dakota Hotel, a large-scale adaptive reuse project at St Ann’s Wharf in Newcastle Upon Tyne.

Hot melt waterproofing systems have long been valued for their robustness, ability to incorporate seamless detailing, and long-term durability. But as the construction industry focuses more sharply on carbon reduction and environmental impact, new product innovations are emerging to help meet sustainability targets.

IKO Permatec LI is one such product – offering all the benefits of the standard Permatec product, but with more than 50 per cent lower embodied carbon and additional sustainability credentials. The system forms part of AccuRoof’s comprehensive roofing portfolio, which covers everything from single ply membrane to slate, and enables the company to provide independent, product-agnostic advice to architects across a wide range of projects.

AccuRoof Technical Director Daniel Bosworth, in conversation with Architecture Today’s Technical Editor John Ramshaw, explains how IKO Permatec LI supports environmentally responsible design, while maintaining the integrity and versatility specifiers expect from hot melt waterproofing.

IKO Permatec LI was chosen for its combination of technical performance and sustainability benefits.

What is hot melt roofing?

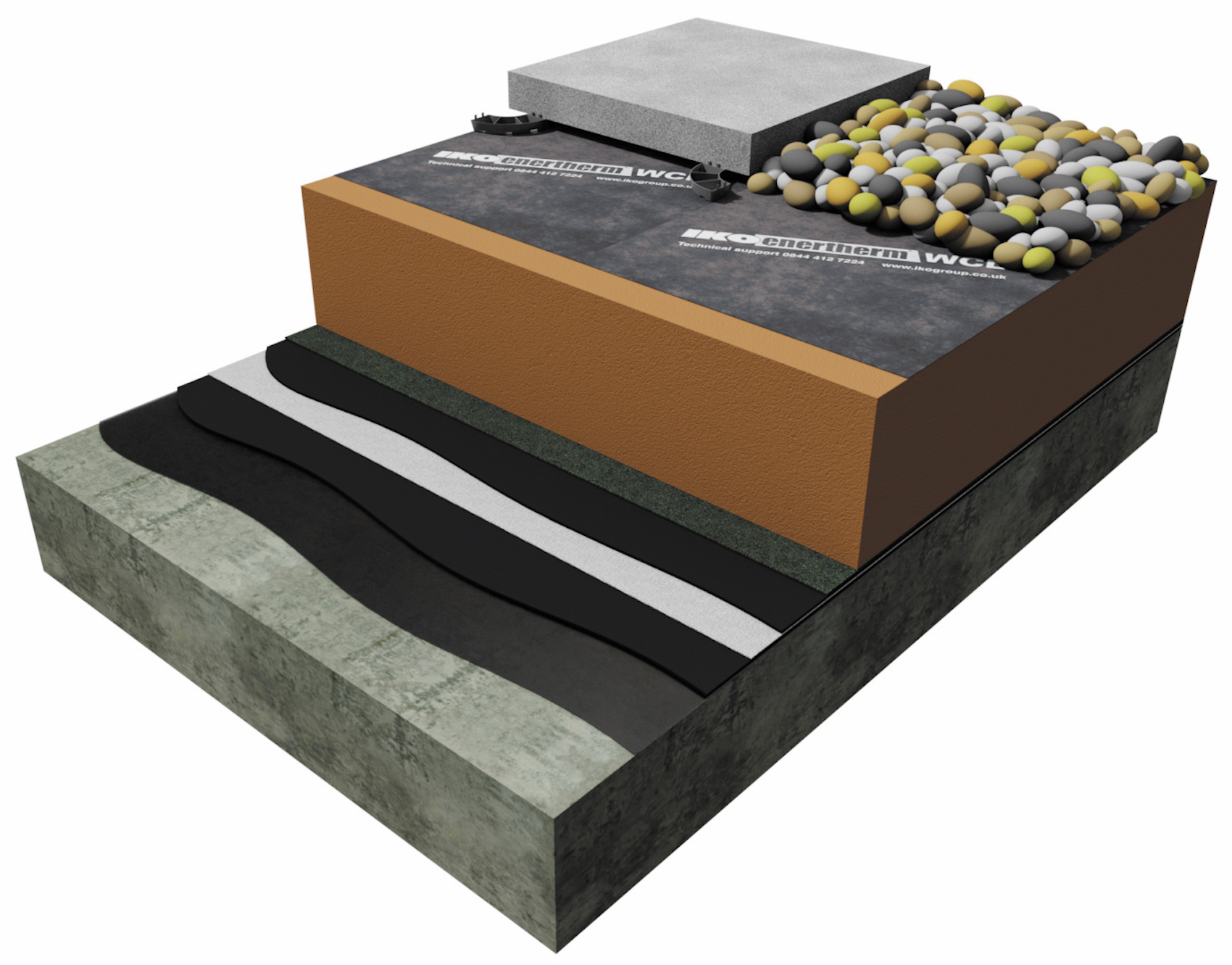

Hot melt is a bitumen-based waterproofing system designed for inverted roof applications. It consists of a specially formulated combination of refined bitumens, synthetic rubbers, fillers, and other additives, which are applied hot (around 180°C) in conjunction with reinforcement and protection layers. Key properties of hot melt roofing include its high-tensile strength, which provide excellent resistance to damage from impact, punctures, and tears. Durability is further enhanced by the product’s seamless, monolithic membrane.

What is different about IKO Permatec LI compared to the standard IKO Permatec?

The key difference is its environmental performance. IKO Permatec LI offers a third-party verified Environmental Product Declaration (EPD) which, when compared to the standard Permatec EPD, is a reduction in embodied carbon of more than 50 per cent. It achieves a Global Warming Potential (GWP) of 150kg CO₂e per tonne of material.

IKO Permatec LI build-up for an inverted ballasted roof.

How has IKO achieved this reduction in embodied carbon?

It’s been achieved by substituting a portion of the crude-oil-derived content of the system with tree resin oil, a bio-based by-product from the paper manufacturing industry. This accounts for approximately 7.5 per cent of the product’s make-up.

Does Permatec LI have any other environmental benefits?

Yes. Like standard Permatec, Permatec LI is supplied in a zero-waste wrapper that melts with the block during heating, eliminating packaging waste on site. The system is also manufactured in the UK at Grange Mill in Matlock, reducing transport-related emissions compared to imported products. Additionally, the long service life of the system – which matches the design life of the building (see BBA Certificate No. 03/4009) – means there should be no need to replace the waterproofing during the building’s lifespan.

What technical standards and certifications does IKO Permatec LI meet?

The IKO Permatec LI system has multiple BROOF(t4) fire performance tests under EN 13501-5, including assemblies with paving ballast and green/blue roof build-ups. It is also BBA certified (Certificate No. 03/4009). Warranties are available subject to specification and project requirements, and any AccuRoof warranties are backed by SIG Trading Ltd.

IKO Permatec LI is suitable for green and blue roofs, as well as a range of solar PV applications.

Can IKO Permatec LI be used on zero-falls decks?

Yes. Permatec LI and its anti-root variant can be used on zero-falls decks, provided the design complies with BS 6229 and avoids any backfalls. This makes it a suitable option for complex roof geometries and refurbishment projects.

Is the covering suitable for green/blue roof and solar roof applications?

Yes. IKO Permatec LI is available in two formulations: standard and anti-root, with the latter incorporating additives that prevent root penetration for green roof applications. The system is also suitable for blue roofs and a range of solar PV applications, including direct fixing, ballasted installations, and biosolar systems where the green roof provides the ballast under the PV array.

How does the roof covering perform under real-world conditions?

Permatec LI hot melt is applied at around 180°C and becomes waterproof as soon as it cools, making it suitable for installation in cool conditions (typically above 5°C). Unlike warm roof systems, inverted roof build-ups – which Permatec LI supports – can tolerate wet weather during installation, as the insulation is installed after the waterproofing layer is complete. This can simplify site programming and reduce the need for temporary night seals.

IKO Permatec LI Anti-Root does not require a separate anti-root membrane when used on green roof applications.

How important is the role of trained installers and technical oversight in ensuring performance on site?

Correct installation is critical to achieving the full lifespan and performance of any waterproofing system. Permatec LI is installed by IKO-trained operatives, and AccuRoof provides ongoing technical support to ensure detailing is carried out in line with British Standards. This includes minimum 150mm upstand heights at thresholds and window junctions, as well as robust treatment of high-risk areas, such as door openings and parapets.

What tools and support does AccuRoof provide to help architects specify the system correctly?

AccuRoof offers a wide range of specification support services, including interface detailing, U-value calculations, condensation risk analysis, and bespoke design advice. The team works with architects and contractors from early-stage design through to installation, ensuring the correct system is specified and correctly implemented on site. Early engagement is encouraged to get the full benefit of AccuRoof’s product-agnostic approach and technical expertise.

Contact details

For more information on IKO Permatec LI, to discuss a project, or request technical support, please call 01509 505 714, email, or visit the AccuRoof website.