Senior Architectural Systems, one of the UK’s largest manufacturers of aluminium fenestration solutions, is set to introduce a new waste reduction initiative as part of its commitment to circularity and working towards a fully closed-loop recycling process. This will see all polyurethane foam waste generated during the manufacture of the patented thermal break in Senior’s low U-value PURe® aluminium windows and doors collected and reused.

Each year, approximately 80 tonnes of polyurethane foam waste is produced as part of the PURe® manufacturing process. This occurs when extra polyols and isocyanate chemicals are injected into the thermal breaks to prevent cold spots during curing. The result is a unique thermal barrier that delivers lower U-values and improved energy performance compared to traditional systems.

However, the process also creates excess cured foam and although this waste has always had the potential to be reused, it has previously been difficult to manage at scale. Senior is now working with a specialist waste partner to chemically break down the expanded and cured polyurethane foam into its original raw components: polyols and isocyanates. These recovered materials will be reintroduced into Senior’s own manufacturing processes, creating a circular system that eliminates landfill disposal.

The initiative is scheduled to be fully operational by the end of the year and once implemented, all recovered materials from the manufacture of Senior’s PURe® windows and doors will be reused internally. This approach is expected to reduce carbon emissions, cut waste, and lessen demand for virgin raw materials.

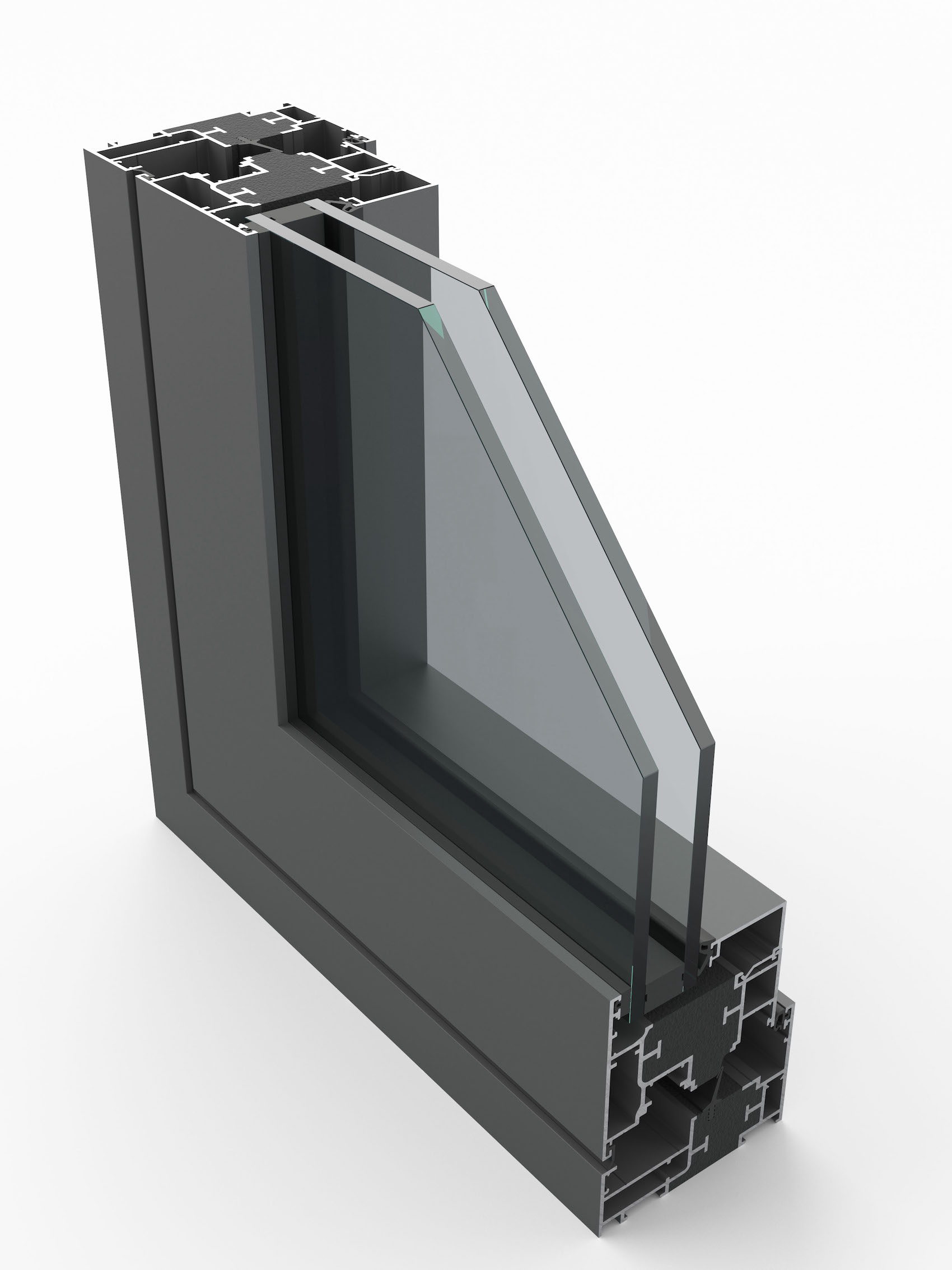

Launched in 2015, Senior’s PURe® system is the first to the UK market to feature an enhanced thermal barrier made from expanded polyurethane foam (PUR). The innovative use of this material, which is traditionally used in cladding and insulation, gives PURe® the potential to achieve U-values as low as 0.71 W/m²K for windows and 0.93 W/m²K for doors, significantly improving energy efficiency and reducing heat loss.

Senior went on to be awarded a UK patent (GB252363.8) for its PURe® system and soon extended its range to cater to both commercial and residential markets. Over the past decade, the PURe® range has evolved to offer a variety of configurations, including casement, tilt and turn, and parallel push windows, as well as folding sliding, inline sliding, lift and slide, single, and double doors. Senior added further strength to the range in 2019 with the launch of the PURe® Commercial Door – the manufacturer’s largest, strongest and most flexible aluminium door system to date. Most recently Senior collaborated with supply chain partner and composite door supplier Hallmark Doors and Panels Ltd to develop a new residential entrance door that combines the patented PURe® thermal efficiency with PAS 24 security.

Senior has also won a number of prestigious awards for the design and development of its PURe® range including the King’s Award for Enterprise in Innovation in 2023.

For more information, please visit www.seniorarchitectural.co.uk or search for Senior Architectural Systems on LinkedIn, Instagram, and Facebook.