When designing the external building envelope, specifiers should consider anomalies and aspects to avoid or review within current standards and best practice approaches. With Polythene DPC to BS 6515 now recognised as being ‘not suitable’ where there is downward water movement, such as at window and door openings, what approach can address the construction detail more proficiently?

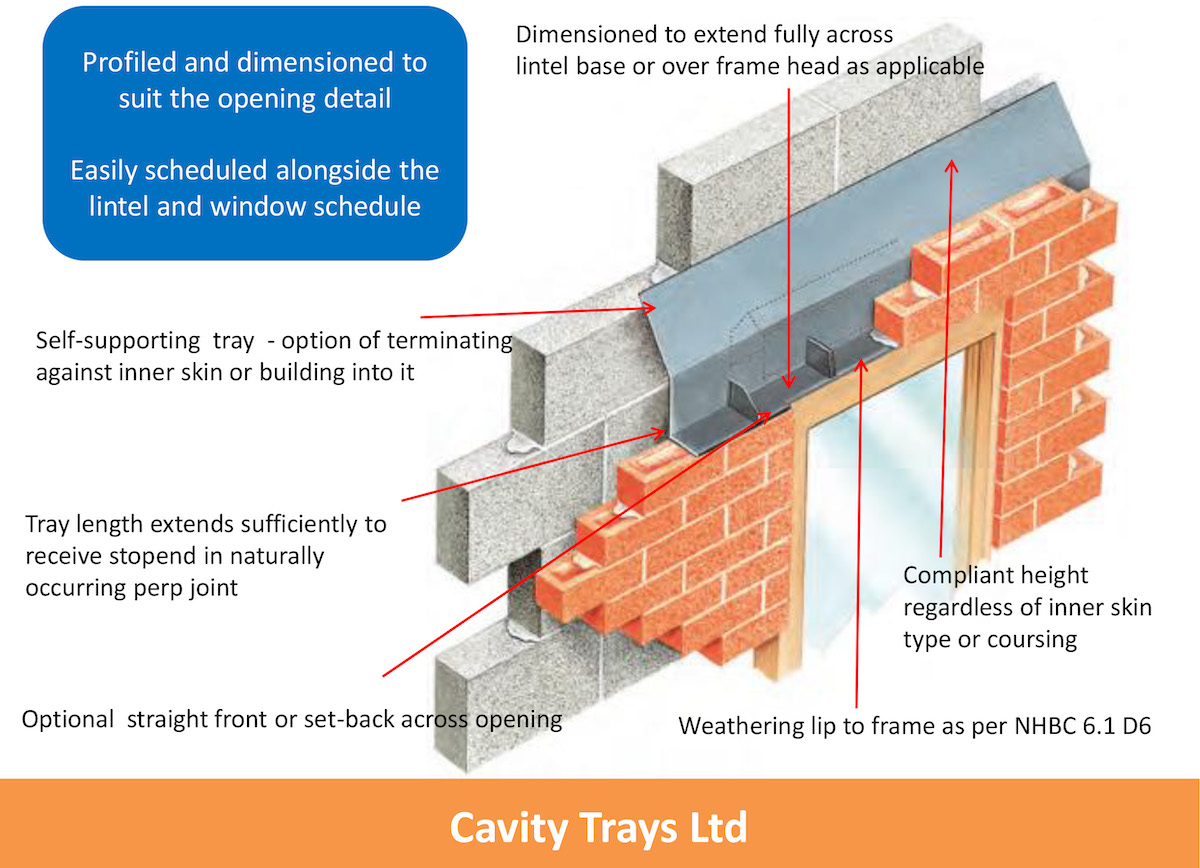

To protect the head of the opening and arrest downward water movement requires an appropriately shaped DPC arrangement to transverse the cavity as it rises to a height of approximately 150mm. If roll DPC is used, it needs supporting to hold it up, and this usually involves building it into the inner skin. Where that inner skin is of standard block work, the available bed courses are at 225mm intervals – so a compliant material of a greater width is required to get there! The material also needs to be sufficiently long to project well past both lintel ends, as stopends will be seeking a naturally-occurring perp joint, and perp joints also normally feature every 225mm with standard bricks.

Using a preformed solid DPC Cavitray offers many benefits, at design stage and during physical construction. Scheduled alongside lintel and window schedules, preformed trays are supplied ready-moulded to suit the opening arrangement so consistent compliant protection is assured every time. Trays are also self-supporting, so seeking that bed course in the inner skin is eliminated.

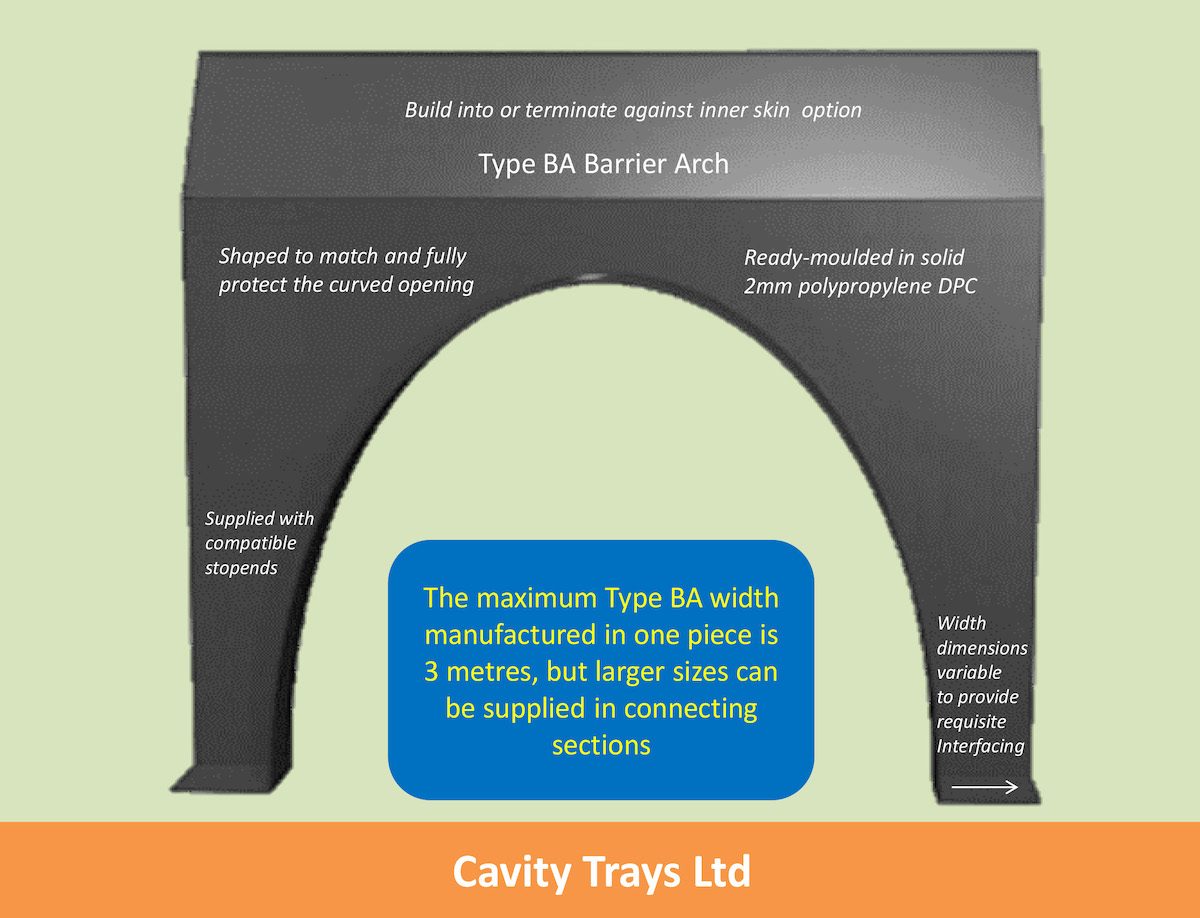

The advantages are amplified further when the opening head is not horizontal, but curved. Preformed arched Cavitrays match exactly the opening radius, providing protection at intrados level, and discharge offset along the springing line. Where numerous arches are in such close proximity that pinch-points are created into which large volumes of penetrating water would normally gravitate, Cavity Trays Ltd has arresting trays to prevent overwhelming.

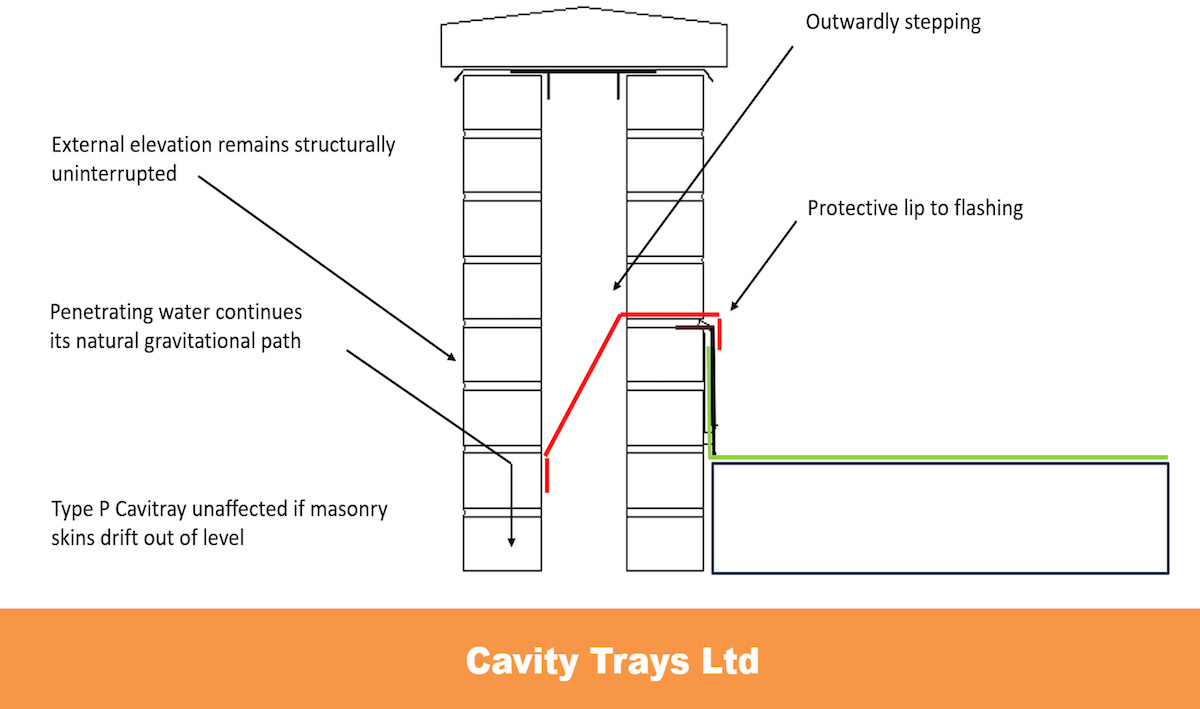

Control of penetrating water is also an important aspect at higher levels – the parapet wall being a good example. A parapet has both masonry skins exposed to the elements and should be accompanied with an understanding the internal DPC configuration always steps downwardly and outwardly. Unfortunately PD 6697 advises it may step inwardly if there is no cavity insulation present. This is considered incorrect guidance as stepping inwardly exposes the structures’ elevation to wet penetrating and under-tracking the inward-step, especially where cracking occurs long the bedding course – a common occurrence because both high-level skins are structurally separated from the masonry under! Using preformed Cavitrays that step outwardly prevents under-tracking, and Type P parapet trays are also self-supporting, so banish the need to build into the elevation skin which remains structurally uninterrupted.

By eliminating errors arising from on-site fabrication using Cavitrays unaffected by deviating skin levels and circumventing PD 6697 ambiguities, preformed Cavitrays offer the designer consistent and compliant construction solutions.

Understanding construction water penetration routes has been the focus of the Cavity Trays team in Yeovil since the founder family started manufacturing one hundred years ago. It is the longest-established specialist in its field and the only UK cavity tray manufacturer awarded European Technical Approval. Its approved Cavitrays are accompanied with a performance warranty.

Cavity Trays

T: 01935 474769

enquiries@cavitytrays.co.uk

www.cavitytrays.com