Rachel Hoolahan, Associate Director at Orms, has produced a School of Specification module on Materials Passports. She considers the advantages and challenges of implementing materials passports as well as how project teams can start using them.

What are materials passports and why are they important?

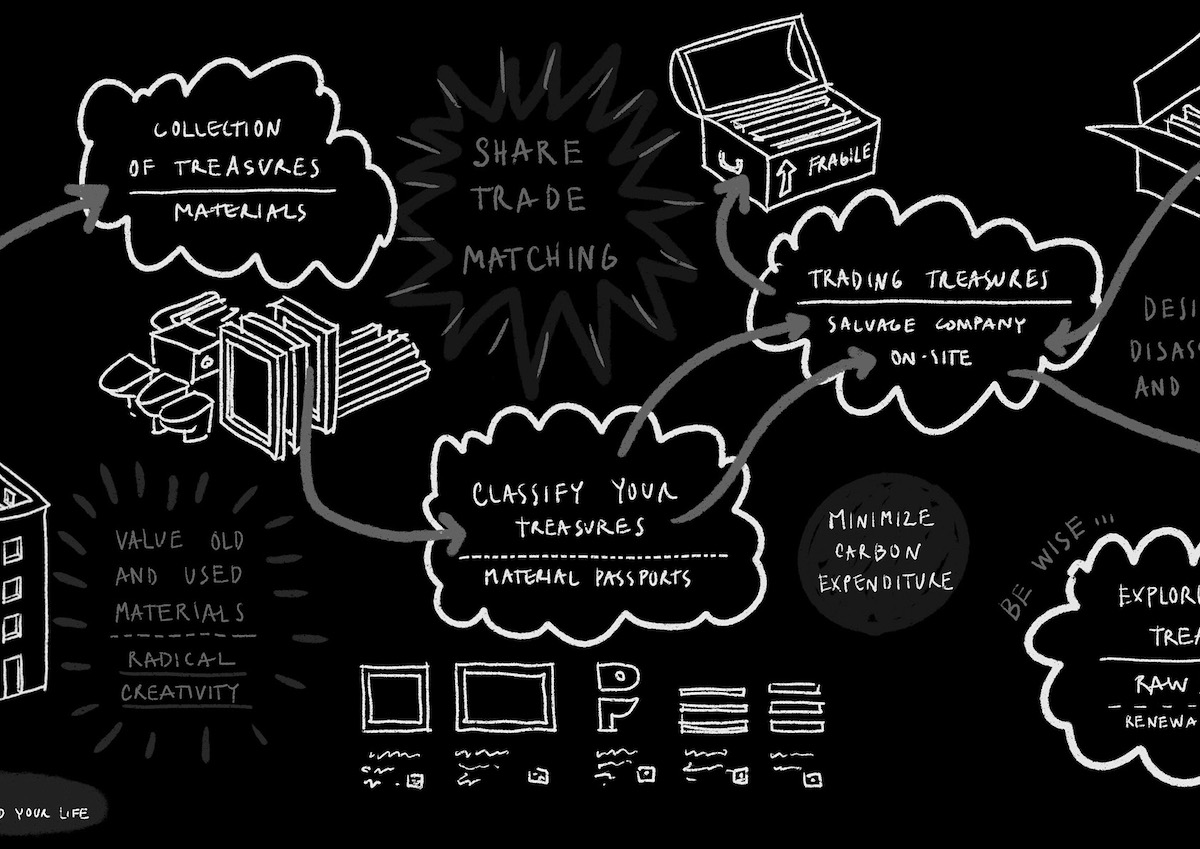

Materials passports are digital sets of data that describe the defined characteristics of materials and components in buildings, giving them value for present use, recovery, and future reuse. Think of them as identity cards for building materials that travel with those materials throughout their lifecycle. In an especially resource-intensive industry, materials passports offer a crucial tool for change. They allow us to track materials’ origins, properties, performance characteristics, and potential end-of-life scenarios, providing the information necessary to extend material lifespans beyond a single building.

How can materials passports be applied across a building’s lifecycle?

Materials passports function at multiple scales throughout a building’s existence. For new buildings, passports should ideally be created at the point of material extraction and enhanced during manufacturing, where materials are transformed into building components. During design and construction, passports are integrated into element and system passports, creating a comprehensive building passport. For existing buildings, even basic materials passports developed during pre-redevelopment or pre-deconstruction audits can significantly increase the reuse potential of those materials. During a building’s operational phase, the passport database provides valuable information for maintenance and refurbishment. At end of life, the database informs deconstruction planning, allowing materials to be carefully harvested rather than demolished, with their passports traveling with them to their next use.

What are the main benefits of using materials passports?

Materials passports offer substantial benefits including:

- De-risking reuse by establishing a due diligence methodology

- Resource efficiency through reduced extraction of raw materials, as more materials are being reused

- Significant embodied carbon reductions by extending material lifecycles

- Waste reduction by giving materials an identity that facilitates reuse

- Future-proofing through design for disassembly and deconstruction

- Improved operations and maintenance, preventing early replacement of materials

In an especially resource-intensive industry, materials passports offer a crucial tool for change”

What challenges exist in implementing materials passports and material reuse?

We’ve identified several barriers to implementing materials passports and material reuse, including:

- Time considerations, as developing the materials passports strategy, and database will require additional resource initially.

- Cost considerations, as disassembly for reuse can be perceived as more expensive than demolishing and buying new.

- Lack of experience and hesitancy in industry. Materials passports are an emerging concept, and as such aren’t a common deliverable on many projects yet.

- Risk perception due to limited data on existing materials and reuse concerns.

- Contemporary construction techniques that favour chemical fixings over mechanical ones.

- Knowledge gaps requiring cross-disciplinary expertise to enable reuse.

- Logistical challenges with the existing supply chain, storage and transportation.

What practical steps can project teams take to start using materials passports today?

Teams looking to implement materials passports can begin with these achievable steps:

- Develop a materials passports strategy that outlines aims, processes and responsibilities.

- Start small – don’t attempt to passport everything in your first project.

- Focus on materials with high reuse potential, high carbon impact or high residual value.

- Use the standardised templates available for structuring your database.

- Adopt the Uniclass classification system to ensure interoperability with other systems.

- Complete a pre-demolition or pre-refurbishment audit for existing buildings to identify reuse opportunities.

- Assign clear responsibilities for data collection among team members.

- Consider using QR codes or other data carriers to link physical materials to digital passports.

- Create a deconstruction plan alongside traditional O&M documentation.

Join Rachel Hoolahan to learn more about materials passports:

www.schoolofspecification.co.uk/courses/materials-passports/