VEKA discusses how its M70 and OMNIA PVCu window and door systems combine contemporary aesthetics with outstanding thermal performance and sustainable manufacturing.

In association with![]()

As architects face tightening building regulations and rising sustainability targets, VEKA’s M70 and OMNIA systems demonstrate how PVCu innovation can meet the demands of contemporary design without compromise. Combining outstanding thermal performance, durability, and recyclability, both systems deliver proven, specification-ready solutions for a more energy-efficient built environment.

Performance for a changing built environment

As the construction industry continues its transition toward net zero, the role of high-performance fenestration in achieving building compliance and carbon targets has never been more important. VEKA, the UK’s largest PVCu systems company, continues to set the standard for thermal efficiency and sustainable manufacturing with two systems: M70 and OMNIA. Each has its own design character and technical strengths, yet both reflect the same uncompromising VEKA standard for performance, durability, and environmental responsibility.

OMNIA side door and tilt-and-turn window.

OMNIA: Design-led innovation with real performance

The OMNIA system represents a new generation of PVCu design, created specifically for architects and specifiers who demand a balance of refined aesthetics and measurable performance. It is a pioneering suite of double-flush, double-rebated windows and doors, designed for exceptional durability and weather protection. Achieving U-values as low as 0.75 W/m²K with triple glazing, OMNIA comfortably exceeds current requirements and aligns with the 2025 Building Regulations.

The true double-flush finish inside and out creates a clean, contemporary aesthetic that mirrors the crisp sightlines of aluminium, yet with all the thermal and cost efficiencies of PVCu. The double-rebate design enhances acoustic control and weather sealing, while precision-engineered fixtures and fittings ensure the system performs reliably over its long lifespan. Available across casement, tilt-and-turn, residential, and French door formats, OMNIA combines visual appeal with engineering integrity.

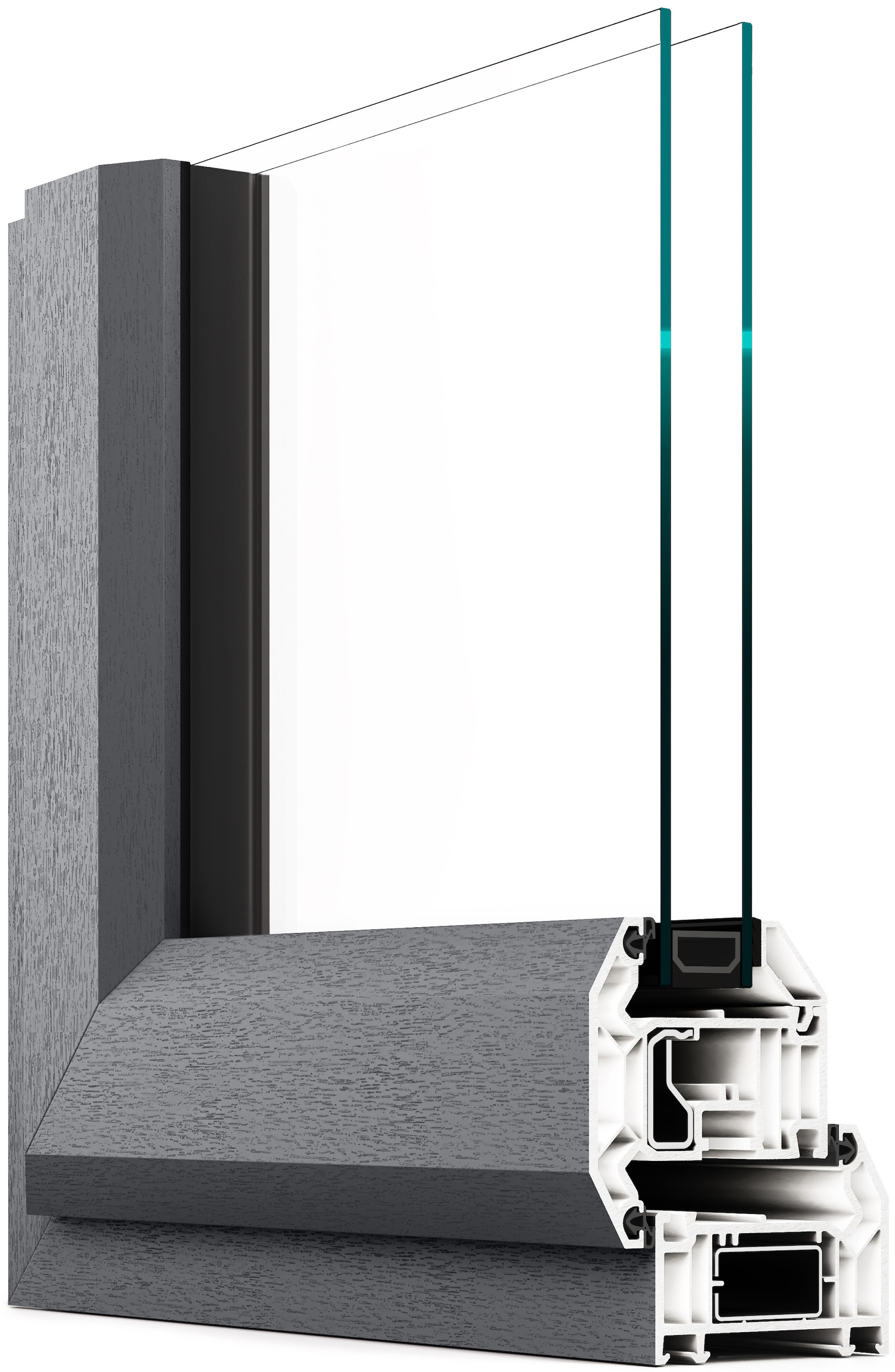

OMNIA tilt-and-turn corner section.

M70: Trusted versatility for every application

If OMNIA represents innovation for design-led projects, M70 remains the trusted benchmark for reliable, versatile performance across a wide range of sectors. The 70mm fully integrated, multi-chambered system combines refined aesthetics with the strength and durability demanded by commercial, public, and residential applications.

With U-values as low as 0.75 W/m²K with triple glazing and 1.2 W/m²K with double glazing, M70 comfortably achieves the efficiency levels required for contemporary building standards. Steel reinforcement within the profile adds rigidity without compromising thermal performance, while the slim sightlines and a 70mm frame depth make it equally suited to retrofit and new-build installations.

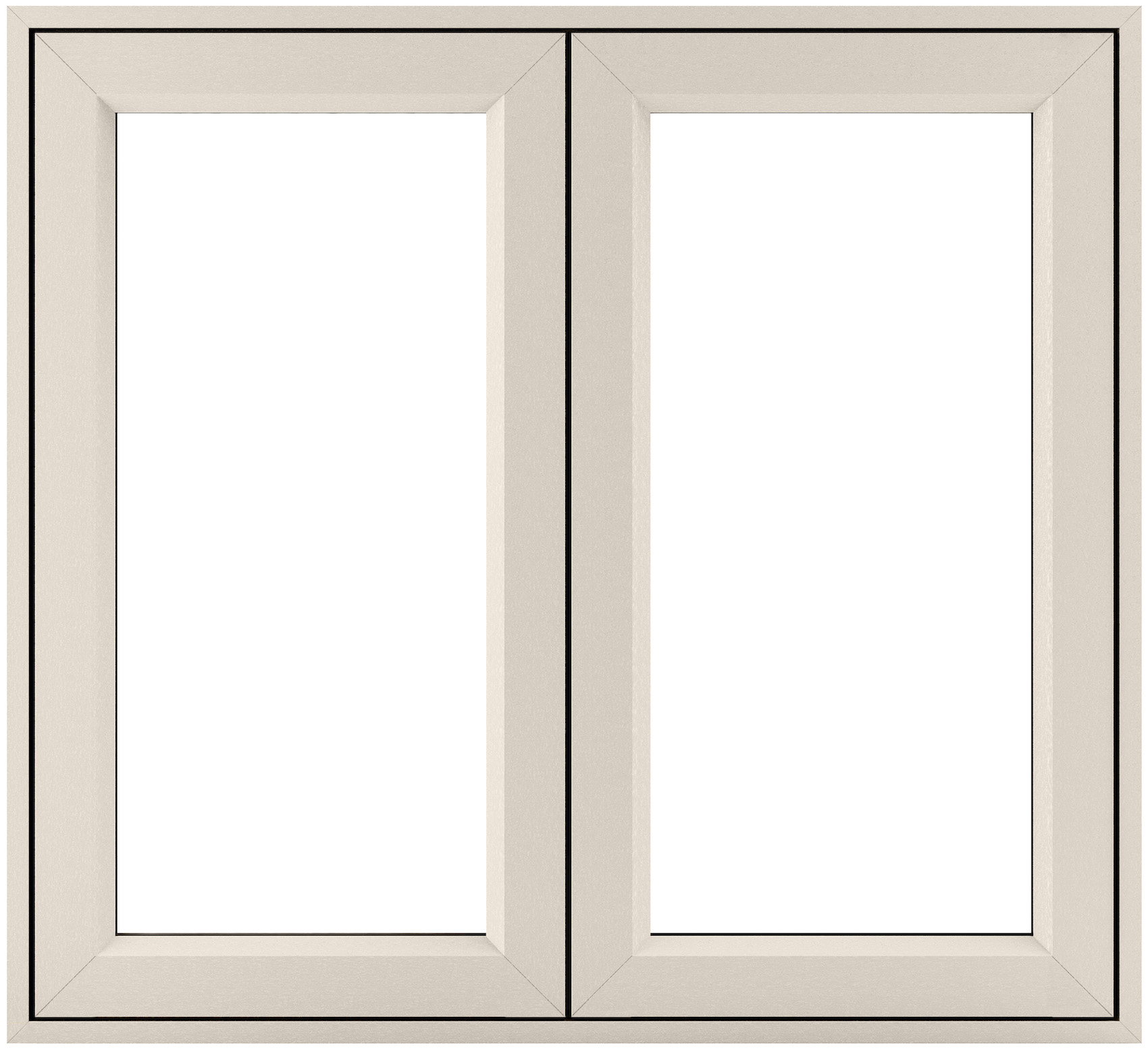

OMNIA casement window.

A shared standard of sustainability and quality

Despite their different designs, both systems share a common foundation: the VEKA standard. Every product is developed to achieve the highest levels of thermal performance, sustainability, and long-term durability. VEKA’s materials and manufacturing processes are engineered for efficiency, from multi-chambered insulation to precision sealing, resulting in window and door systems that contribute significantly to lowering a building’s energy demand and operational costs.

Sustainability sits at the heart of this performance story. VEKA’s Wellingborough-based recycling facility, one of the most advanced in Europe, processes up to 25,000 tonnes of end-of-life PVCu windows and doors each year. In 2024, the facility diverted more than 1.35 million frames from landfill, ensuring that 60 per cent of all recovered material is transformed into new PVCu profiles.

The average PVCu window has a life expectancy of more than 30 years and can be recycled up to ten times, effectively creating a potential material lifespan of over 350 years. This closed-loop approach allows specifiers and developers to demonstrate tangible carbon savings and circular-economy credentials within their projects.

Durability and low maintenance are further hallmarks of VEKA’s PVCu systems. The company’s profiles resist rot, peeling, cracking, and warping, maintaining their appearance and performance over decades of service with minimal intervention. Every window and door system are tested to British Standards for security, weather performance, and cyclic endurance, achieving PAS 24 and Secured by Design accreditation as standard.

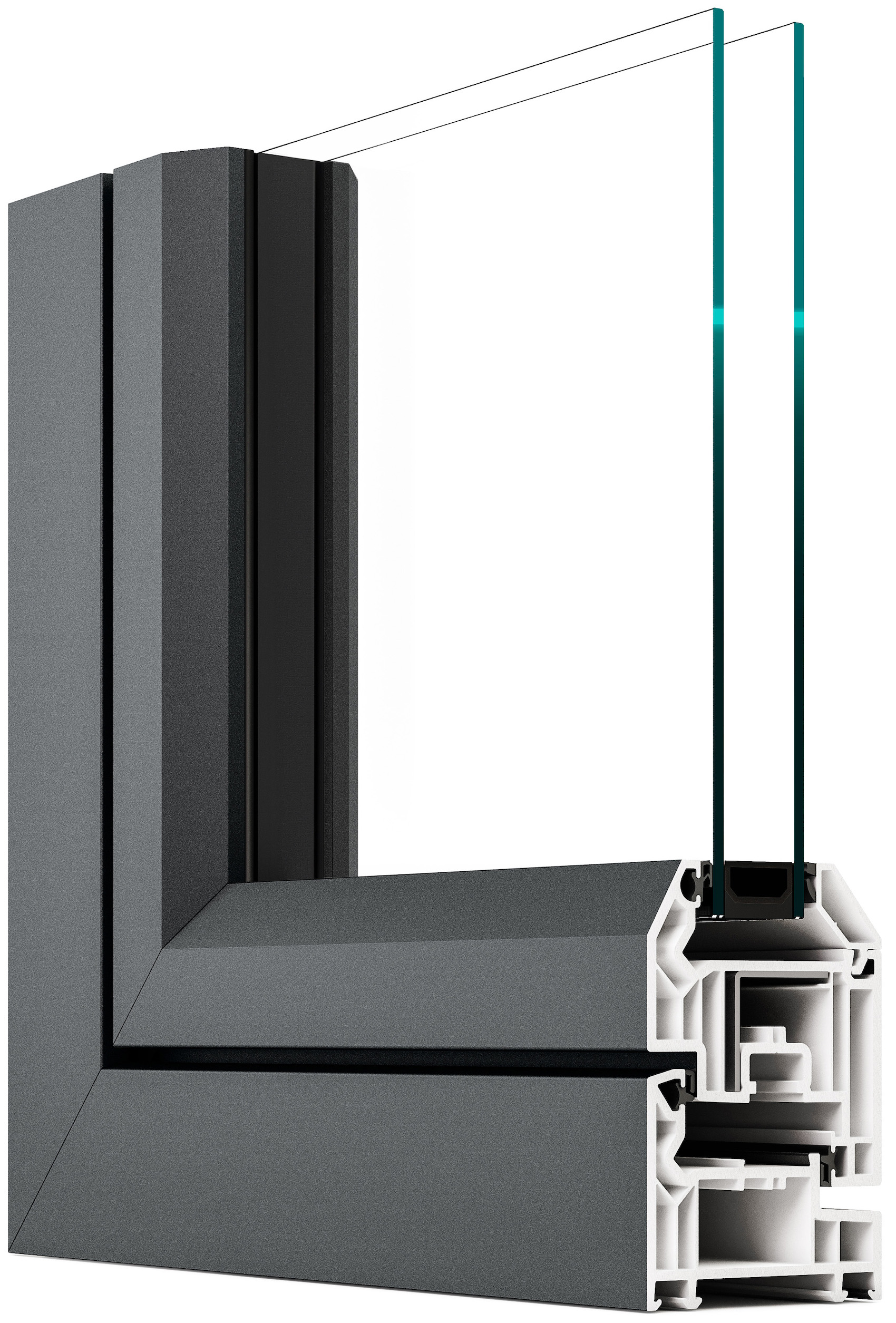

M70 casement corner section.

Futureproofing

Supporting this technical performance is a full suite of specification tools designed to simplify the architect’s workflow. VEKA’s free-to-use WinDoPlan platform provides live access to U-value calculations, wind-load analysis, and 3D visualisation, while BIM-ready data is available through NBS Source. This allows designers and specifiers to evaluate system performance based on project-specific variables, ensuring that each application meets the necessary compliance and design objectives from the outset.

Together, M70 and OMNIA show how PVCu has evolved from a purely functional material into a technically sophisticated, architecturally versatile solution. In a building landscape defined by carbon reduction, energy performance, and long-term resilience, VEKA’s systems provide specifiers with reliable, proven solutions that meet the demands of today while anticipating the standards of tomorrow. Different designs. Same uncompromising performance.

Contact Details

Download the VEKA commercial Brochure here. For more information and technical support, email ukcommercial@veka.com