Sika unveils a 35 per cent lower-carbon roof waterproofing membrane.

In association with![]()

Combining performance with minimised environmental impact, Sika’s flat roofing systems and products protect buildings from all types of climate and weather conditions.

Sika®, a leader in innovative waterproofing solutions, has launched Sikalastic®-625 BMS, an advanced polyurethane liquid applied membrane (LAM) that reduces carbon emissions by more than 35 per cent. Marking a significant step towards sustainable construction, the new product is designed for flat roof waterproofing and incorporates sustainable chemical innovations, such as biomass-balanced materials and bio-based solvents. This approach retains the performance of traditional roofing solutions, while significantly lowering the product’s environmental impact.

The construction industry faces increasing pressure to reduce carbon emissions, particularly in products like roofing membranes that play a critical role in building safety and performance. The challenge has been to integrate renewable, low emissions materials without compromising quality. Sika® has addressed this issue with Sikalastic®-625 BMS, which maintains the versatility and reliability of its current product range, all while meeting the demand for more sustainable solutions.

Sikalastic®-625 BMS is manufactured in the UK at Sika’s Lancashire based site in Preston.

The membrane is a single component, cold-applied, moisture-triggered liquid polyurethane, which quickly forms a durable, weather resistant barrier. It provides the high performance that customers expect from Sika’s products, coupled with a significantly reduced carbon footprint. The product is also low odour, and has improved safety features, making it an ideal solution for sensitive environments like hospitals and schools.

Michelle Round, Technology Centre Manager for Sika’s Global Team, emphasised the importance of this development, stating: “The launch of Sikalastic®-625 BMS marks a step change by using one of our most popular products to aid the transition to net zero. Not only do our customers benefit by reducing their roof waterproofing carbon footprint by over 35 per cent, but it also sends a strong signal to our suppliers that there is demand in the supply chain for more sustainable solutions.”

Fuelling the future: Sustainable materials from Biomass crops.

The introduction of Sikalastic®-625 BMS follows years of dedicated research and development aimed at addressing the construction industry’s growing demand for low-carbon construction solutions. By integrating renewable raw materials, Sika has achieved a substantial reduction in the product’s carbon footprint, without sacrificing durability or ease of application. This membrane is particularly important as it helps drive the roofing sector toward more sustainable building practices.

The development of Sikalastic®-625 BMS involved an advanced computational screening approach that allowed the company to quickly identify bio-based and safer solvents from an extensive database. This accelerated the product’s research and development phase, helping to meet the increasing demand for more sustainable building solutions.

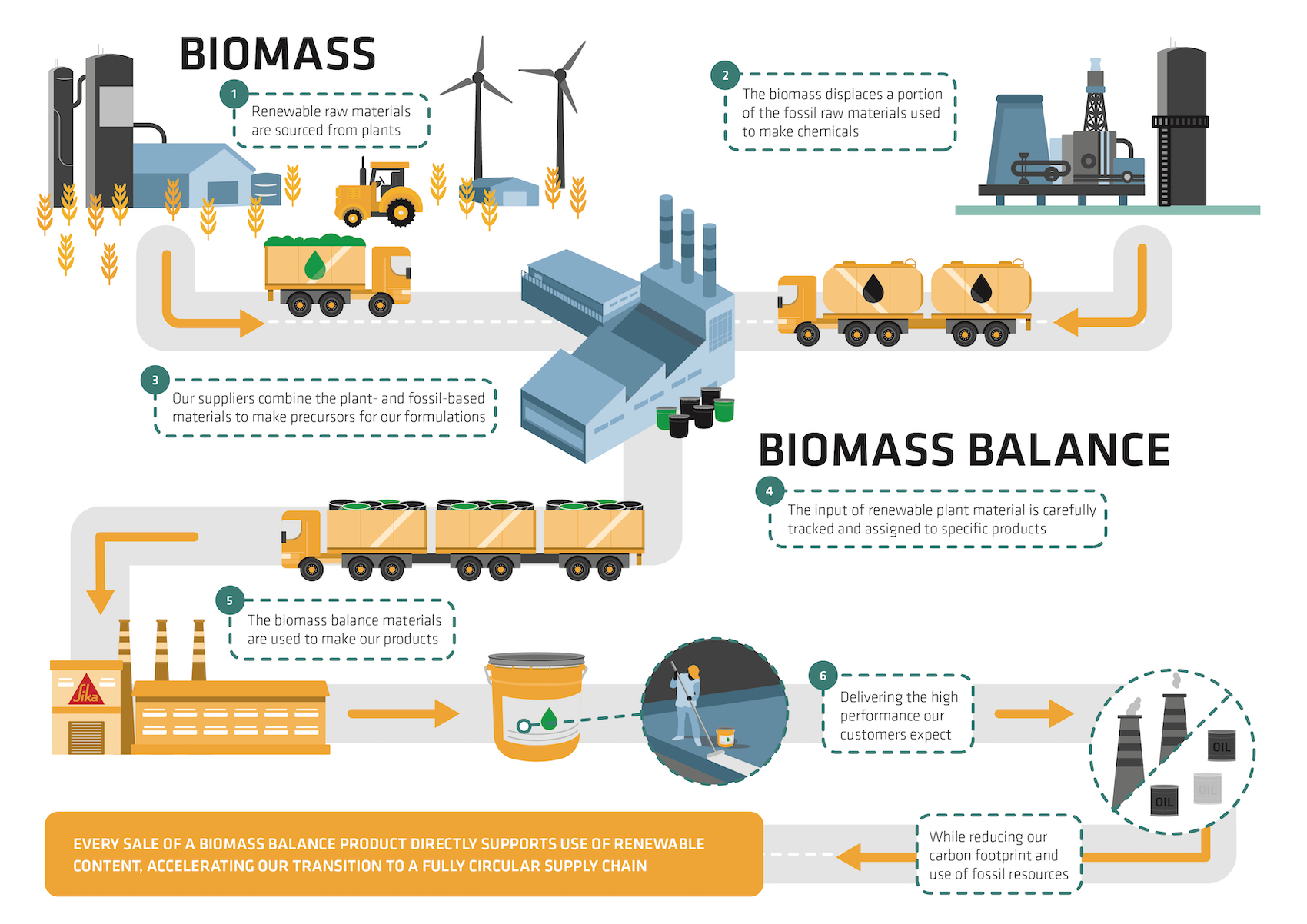

An infographic to show the Biomass Balance approach, supporting the use of renewable content.

A key element in reducing the carbon footprint of Sikalastic®-625 BMS is the use of biomass-balanced materials. These materials serve as a drop-in replacement for fossil-based resources, reducing greenhouse gas emissions without altering product performance. The biomass balance approach involves replacing fossil resources in the supply chain with renewable, plant-based materials, which are tracked to ensure that the sustainable inputs match the final marketed products. This method enhances transparency and accelerates the transition to a circular, net-zero supply chain.

The use of bio-based solvents not only reduces emissions but also improves safety features, making the product non-flammable. The membrane is also low-odour and is certified by Olfasense, which confirms its suitability for sensitive locations, such as hospitals, schools, and food manufacturing plants. Additionally, Sikalastic®-625 BMS has received certification from the British Board of Agrément (BBA), ensuring that the product meets rigorous national and European standards for performance and quality. TÜV Rheinland has also certified the product’s carbon footprint, providing customers with confidence in the genuine sustainability benefits of the membrane.

Sika’s Global Technology Centre based in Lancashire, where Sikalastic®-625 BMS has been developed.

Sikalastic®-625 BMS offers architects, specifiers, and contractors a robust, environmentally-friendly option for roof waterproofing. The product not only meets but exceeds the stringent requirements of modern building projects, offering superior performance, sustainability, and safety. Through this innovation, Sika continues to lead the construction industry’s transition to more sustainable practices while maintaining the high standards its customers expect.

Contact Details

To find out more about Sikalastic®-625 BMS, please call 01707 394444, email, or visit the Sika website.