James Hardie explains how its fermacell® fibre gypsum boards are redefining environmental standards in commercial and timber-frame construction.

In association with![]()

In the evolving landscape of sustainable architecture, material choice is no longer just a matter of performance – it’s a statement of environmental responsibility. Among the frontrunners in this movement is James Hardie with its brand fermacell®, whose EPD-verified fibre gypsum boards are redefining standards in commercial and timber-frame construction.

What sets fermacell® fibre gypsum boards apart is their carbon-storing capability throughout the entire product life cycle. Thanks to optimised recycling processes and responsible raw material sourcing, the boards don’t just reduce emissions – they store CO₂*. This makes them a powerful ally in the fight against climate change and a compelling choice for architects committed to low-carbon design.

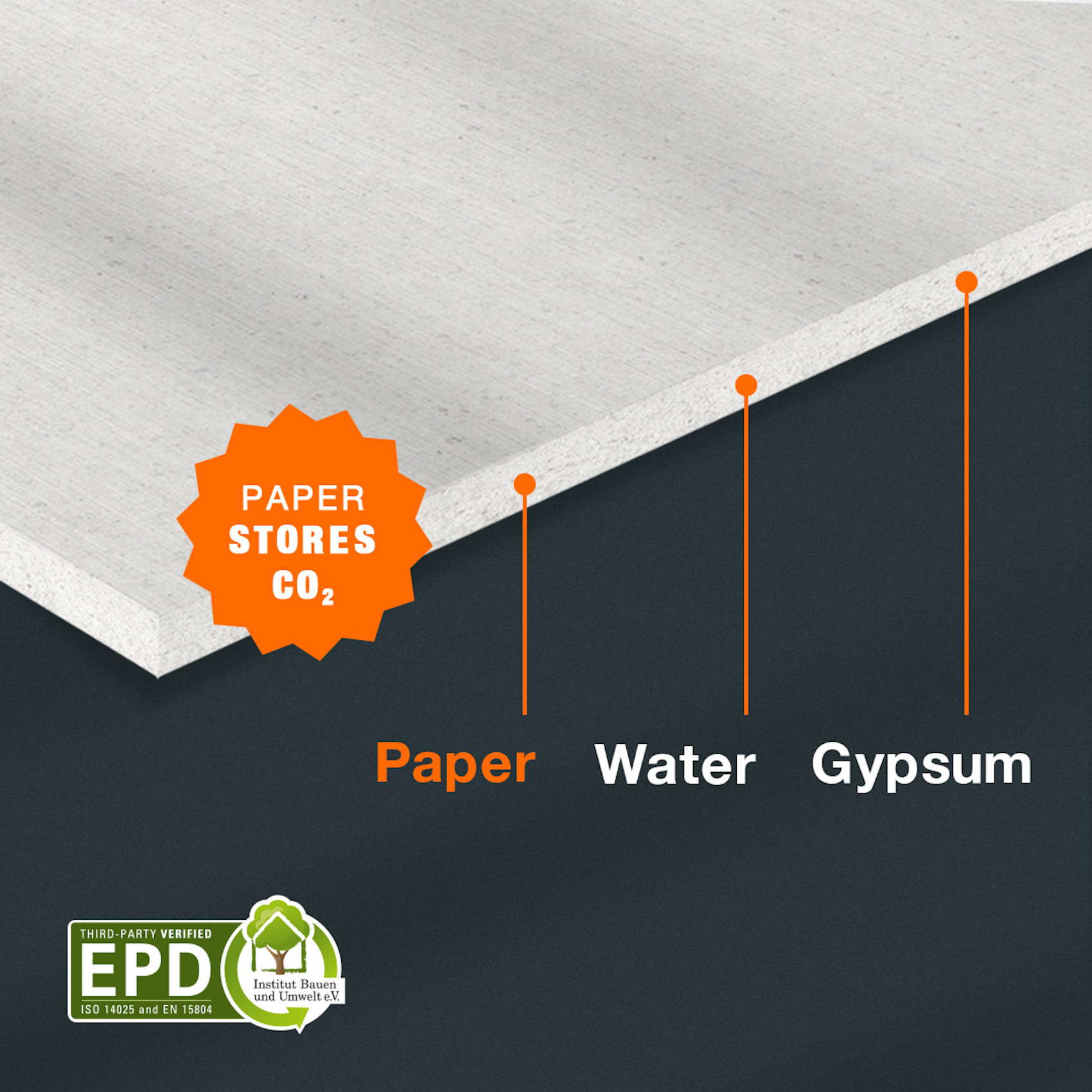

Unlike traditional gypsum boards, fermacell® fibre gypsum boards are manufactured using a unique combination of recycled paper fibres, gypsum, and water – without any added adhesives. This not only enhances their structural integrity but also ensures a clean, closed-loop production cycle. The result is a product that’s robust, versatile, and environmentally sound.

From a design perspective, fermacell® fibre gypsum boards offer exceptional loadbearing capacity, racking strength, fire resistance, and acoustic performance, making them ideal for high-specification commercial interiors and multistorey timber-frame buildings. Their ability to support heavy fixtures without additional reinforcement simplifies installation and reduces material waste – an often overlooked contributor to a project’s carbon footprint.

The Environmental Product Declaration (EPD) verification provides architects with transparent, third-party-certified data on the product’s environmental impact. This is crucial for projects aiming to meet BREEAM certification standards, where material selection plays a pivotal role in achieving sustainability targets.

In timber-frame construction, where the emphasis is on lightweight, high-performance materials, fermacell® boards shine. Their dimensional stability and moisture resistance make them particularly suited to off-site prefabrication and modular building techniques –both of which are gaining traction as efficient, low-impact construction methods.

But perhaps the most compelling reason to specify fermacell® fibre gypsum boards are their contribution to carbon positive building strategies. By storing CO₂* rather than emitting it, the boards help offset the embodied carbon of other materials used in a project. This aligns perfectly with the architectural shift toward regenerative design, where buildings don’t just do less harm, but actively improve the environment.

As the industry moves toward net-zero targets, architects must look to embrace materials that support long-term ecological balance alongside aesthetics and functionality. fermacell® fibre gypsum boards offer a rare combination of technical excellence and environmental integrity, making them the number one choice for forward-thinking commercial and timber frame projects.

In a world where every design decision carries environmental weight, choosing fermacell® is more than a specification – it’s a commitment to building better.

Contact Details

For more information, please visit the fermacell® website.

*CO₂ storing refers to production stages A1-A3 of EPD.