Luxembourg’s first 3D-printed home tackles the country’s prominent housing crisis, producing an economical and environmentally responsible solution.

Luxembourg-based practice ODA Architects has completed the country’s first 3D-printed home. Designed to occupy leftover plots scattered among regular residential neighbourhoods, Tiny House looks to offer affordable, environmentally conscious and practical housing for young people who wish to stay in their neighbourhood but are being forced to leave due to a housing shortage and rising prices.

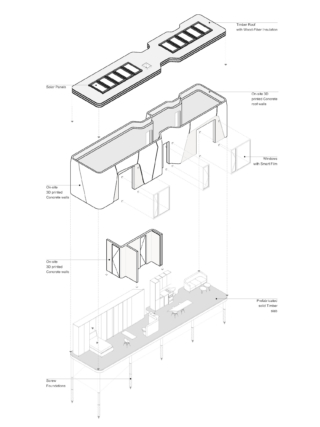

With speed of delivery a priority, the project’s overarching idea is a design-to-print pipeline that turns an architectural vision into a robotic toolpath to create a home in roughly four weeks.

The architects worked in close collaboration with the Municipality of Niederanven to address the excess land that sits idle, often written off for being too narrow or irregular for conventional building. Making up a large proportion of potential housing sites, these spaces are often found in the centre of close-knit communities.

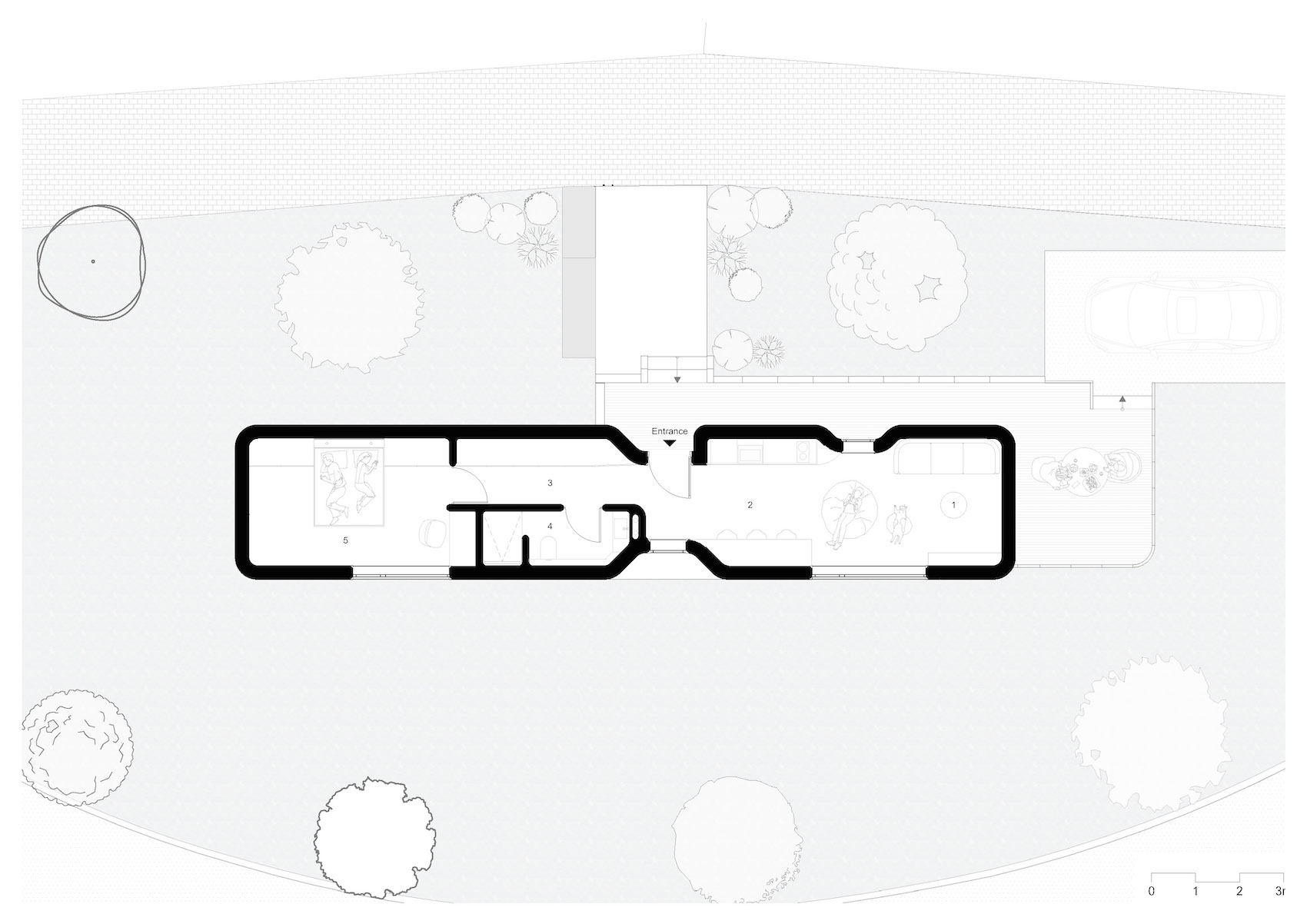

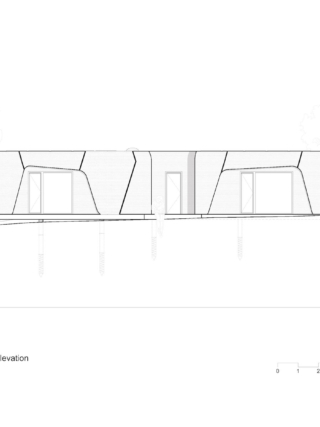

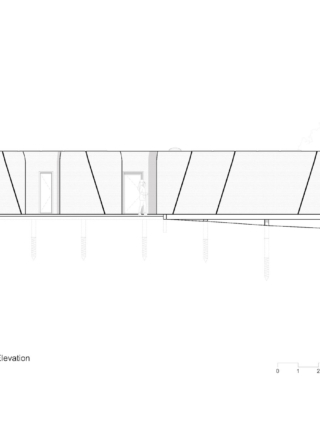

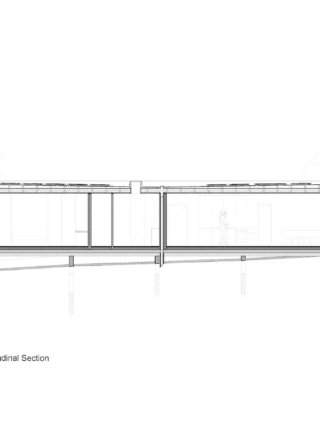

Tiny House sits on a long, tight site at the edge of a residential area in Niederanven, with the plot measuring 600 square metres. The house itself measures three and a half metres wide and 17.7 metres deep, yielding a net usable area of 47 square metres.

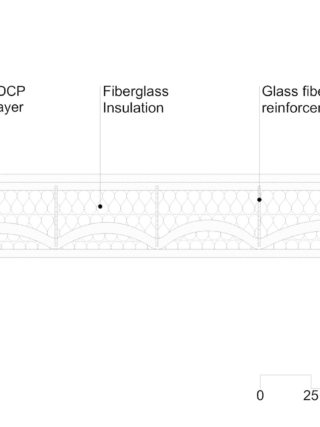

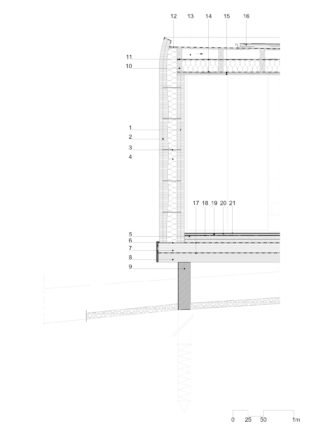

ODA is an interdisciplinary studio of architects, designers and researchers, who partnered with Coral Construction Technologies to propose the adaptable design-to-print housing solution. The house’s concrete walls are printed around a wooden frame onto a timber floor, which sits on screw foundations. The roof structure is also made from wood, being topped with solar panels.

In terms of material sourcing, the ‘printable’ concrete comes from local batching plants, while the insulation is made from natural materials with no synthetic components.

The house has a living room, kitchen and dining space, entrance hall, bathroom and bedroom, but it can be adapted in size and shape depending on the site’s constraints. The nature of the digitally fabricated design allows elements to be formed directly during printing. For example, the shower niche and the cavity for a wall-mounted toilet are printed as part of the wall build-up, reducing construction time, waste, and ultimately saving on cost and carbon emissions.

Credits

Client

Commune de Niederanven

Architect

ODA Architects

Construction

Georgios Staikos, Staikos 3D

3D Print

Coral Construction Technologies